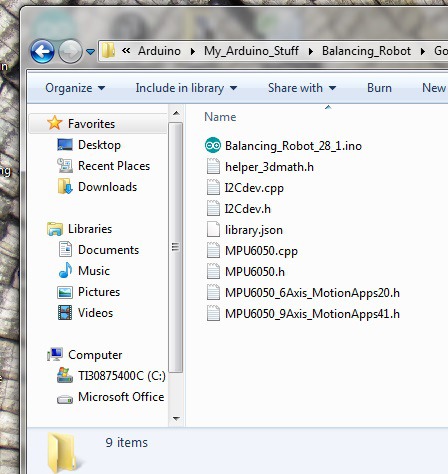

The Arduino SDK https://www.arduino.cc/en/Main/Software has been updated since I last worked on this, and the latest version gave me this error when compiling.

This was due to where the libraries were.

libraries\MPU6050\xxxI2Cdev.cpp.o (symbol from plugin): In function `I2Cdev::I2Cdev()’:

(.text+0x0): multiple definition of `I2Cdev::I2Cdev()’

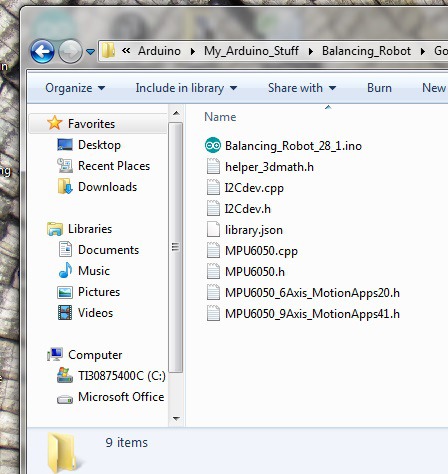

You won’t get an error if you put the header files in with the program file like so

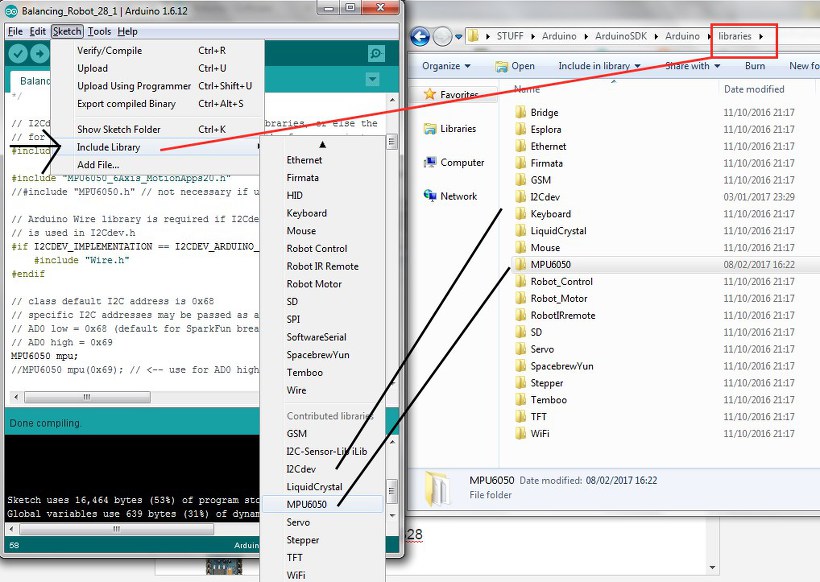

But if like me you prefer to keep your libraries in the Arduino Libraries folder

and add them using the Include Library tab like this

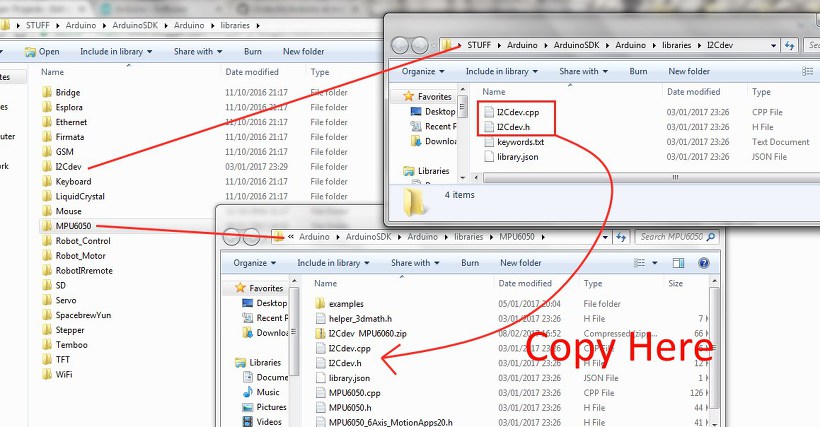

Then

because the header file MPU6050_6Axis_MotionApps20.h already includes (#include”I2Cdev.h”)

#ifndef _MPU6050_6AXIS_MOTIONAPPS20_H_

#define _MPU6050_6AXIS_MOTIONAPPS20_H_

#include “I2Cdev.h”

#include “helper_3dmath.h”

// MotionApps 2.0 DMP implementation, built using the MPU-6050EVB evaluation board

#define MPU6050_INCLUDE_DMP_MOTIONAPPS20

#include “MPU6050.h”

you may see the above error. The compiler looks for I2Cdev.h in the MPU6050 folder

but its not there! So copy I2Cdev.cpp & I2Cdev.h from I2Cdev Folder to

the MPU6050 Folder then add libraries….

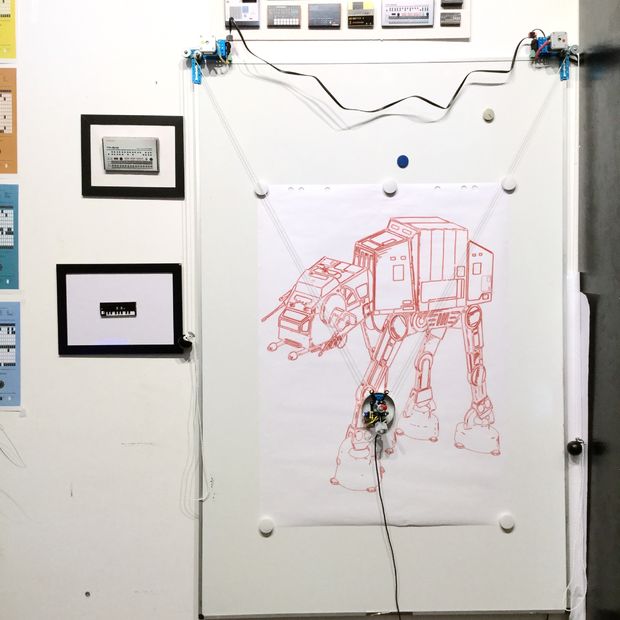

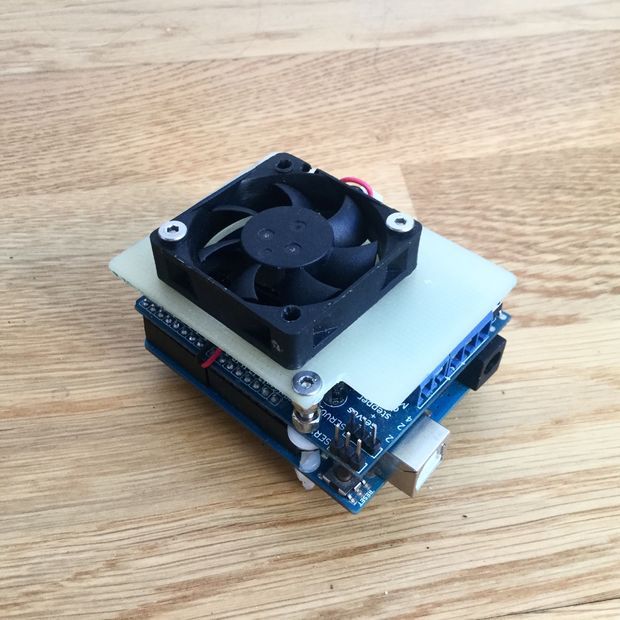

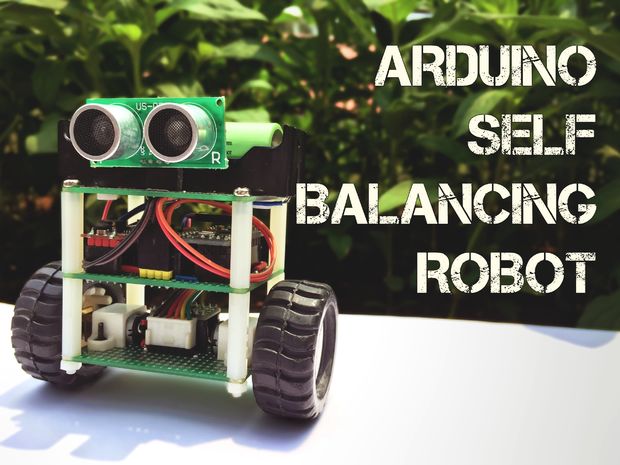

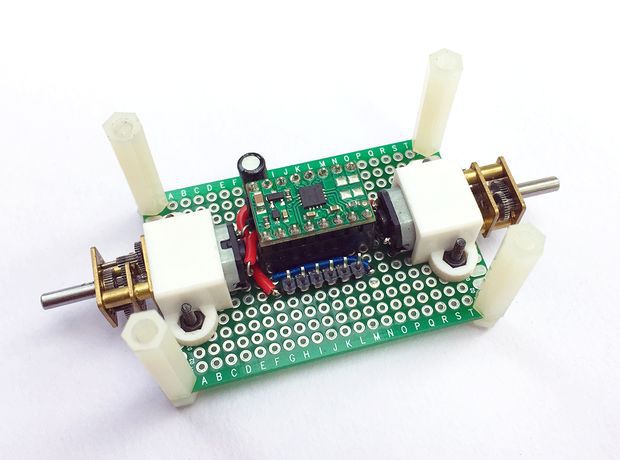

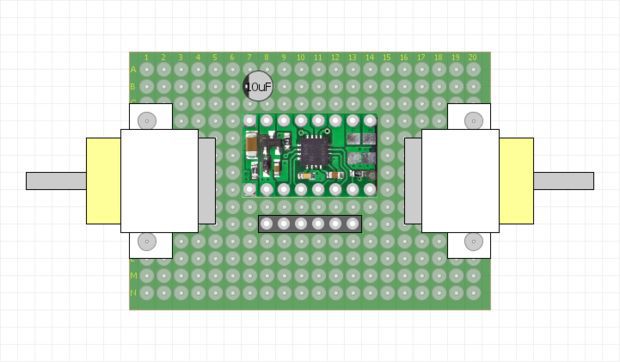

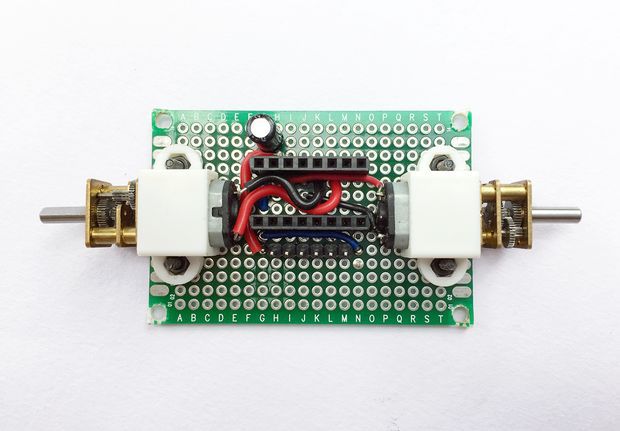

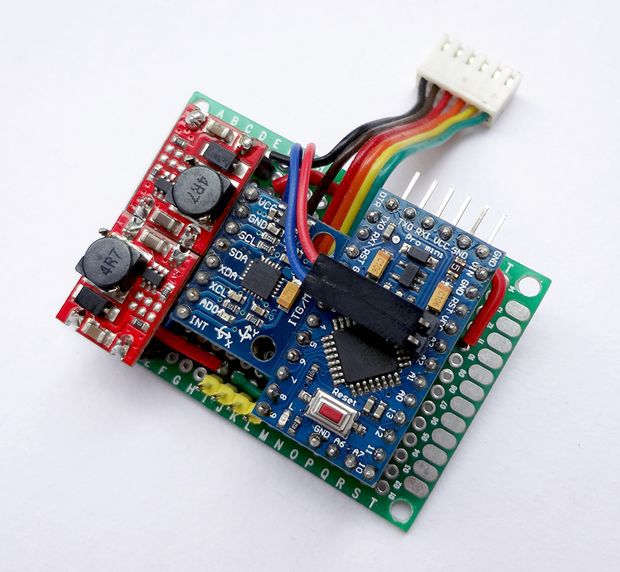

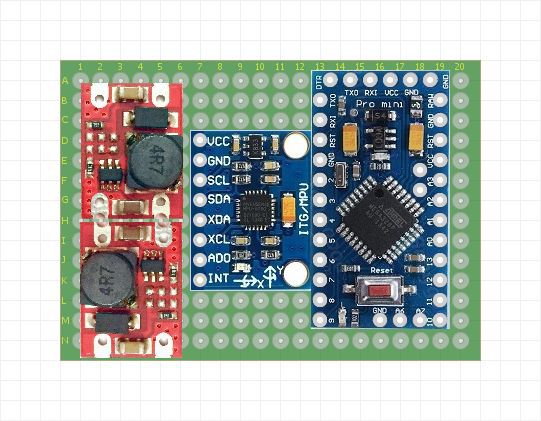

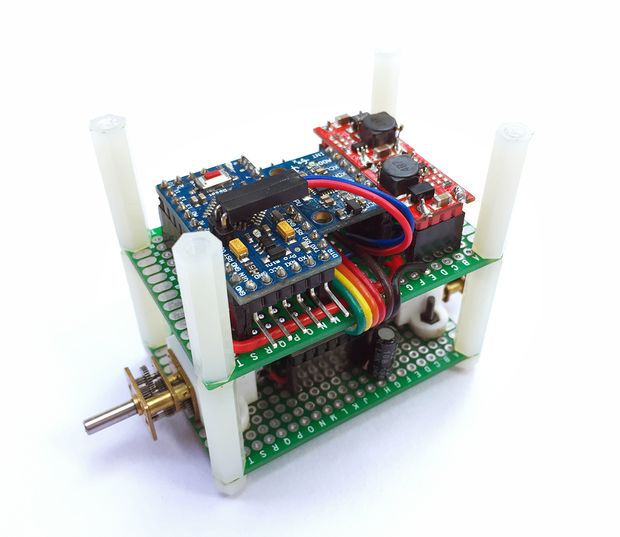

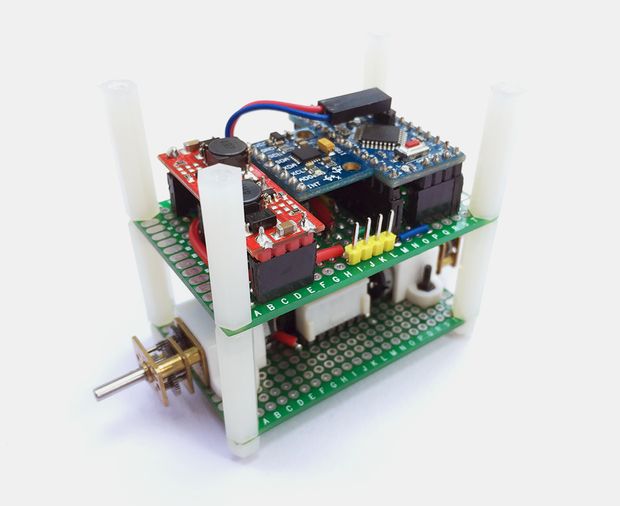

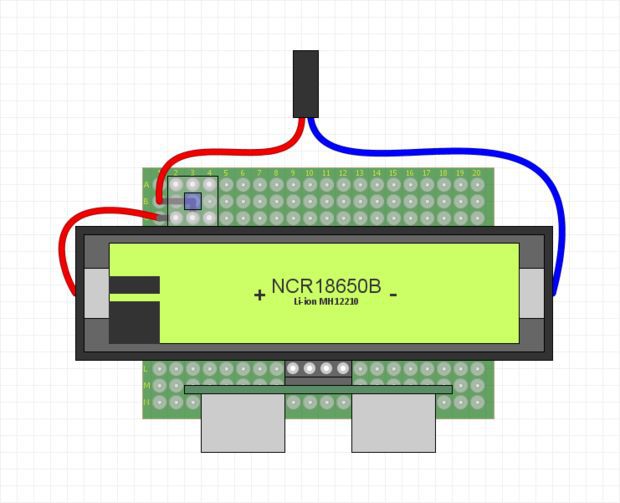

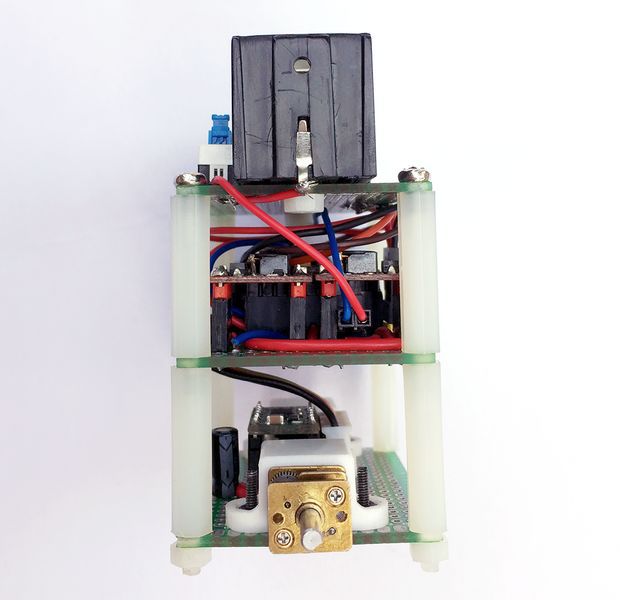

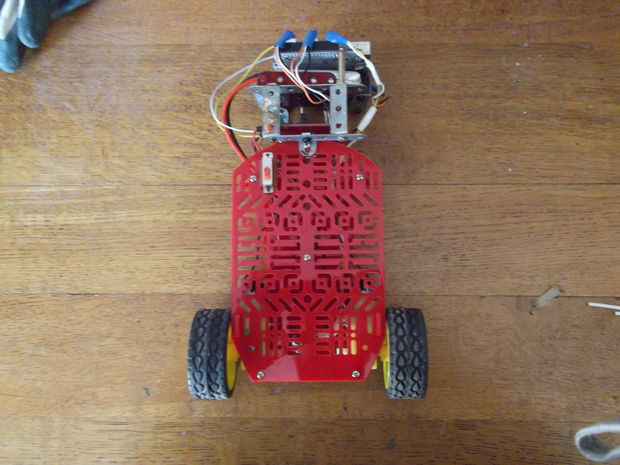

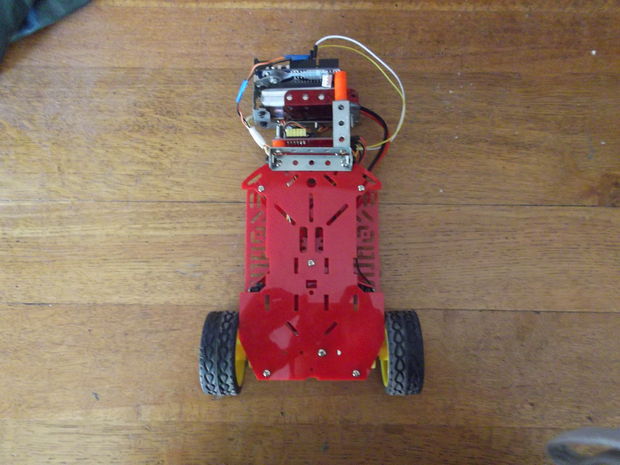

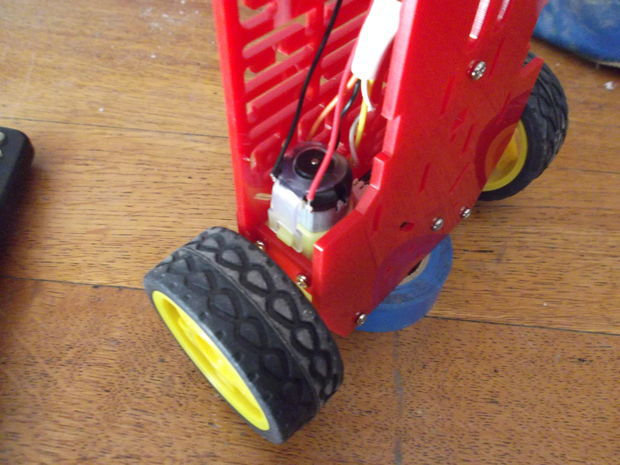

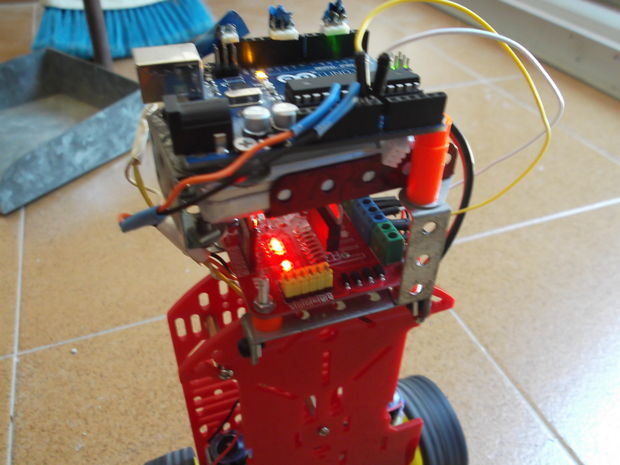

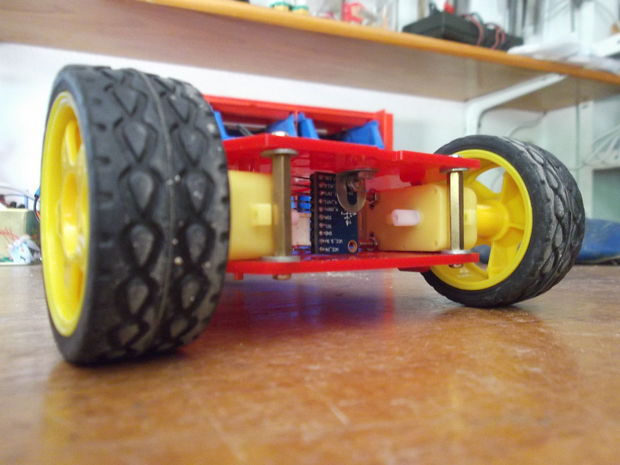

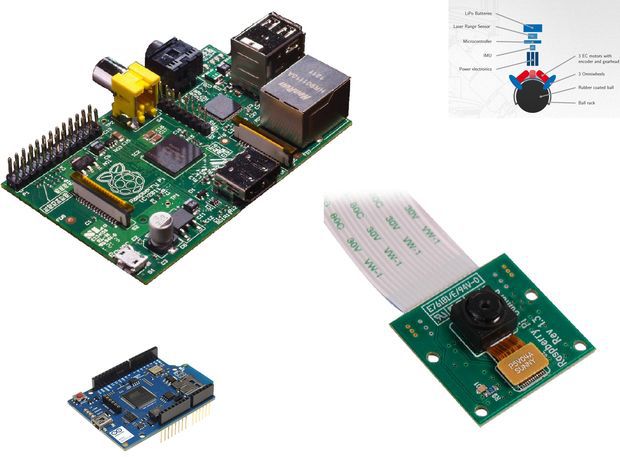

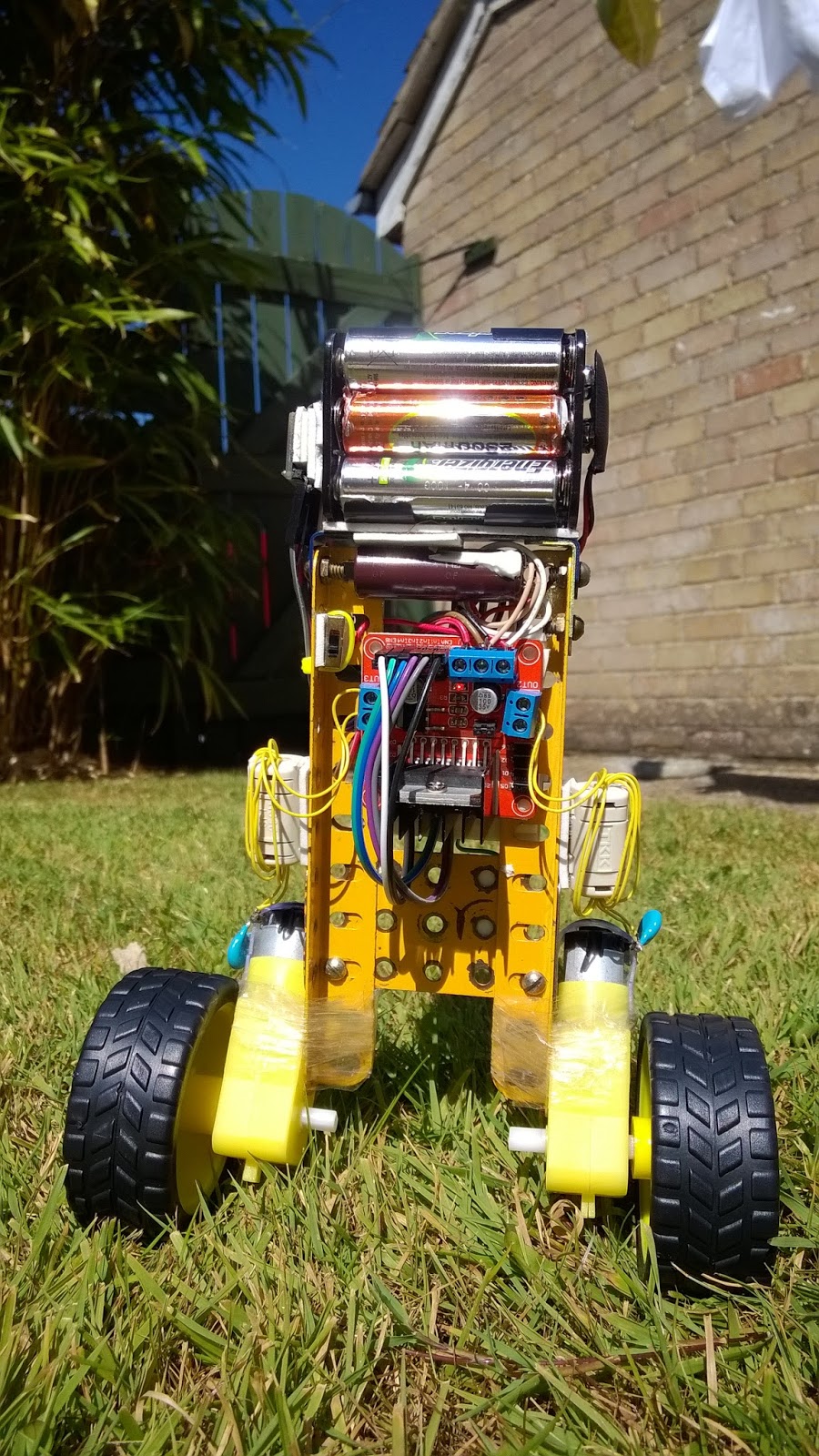

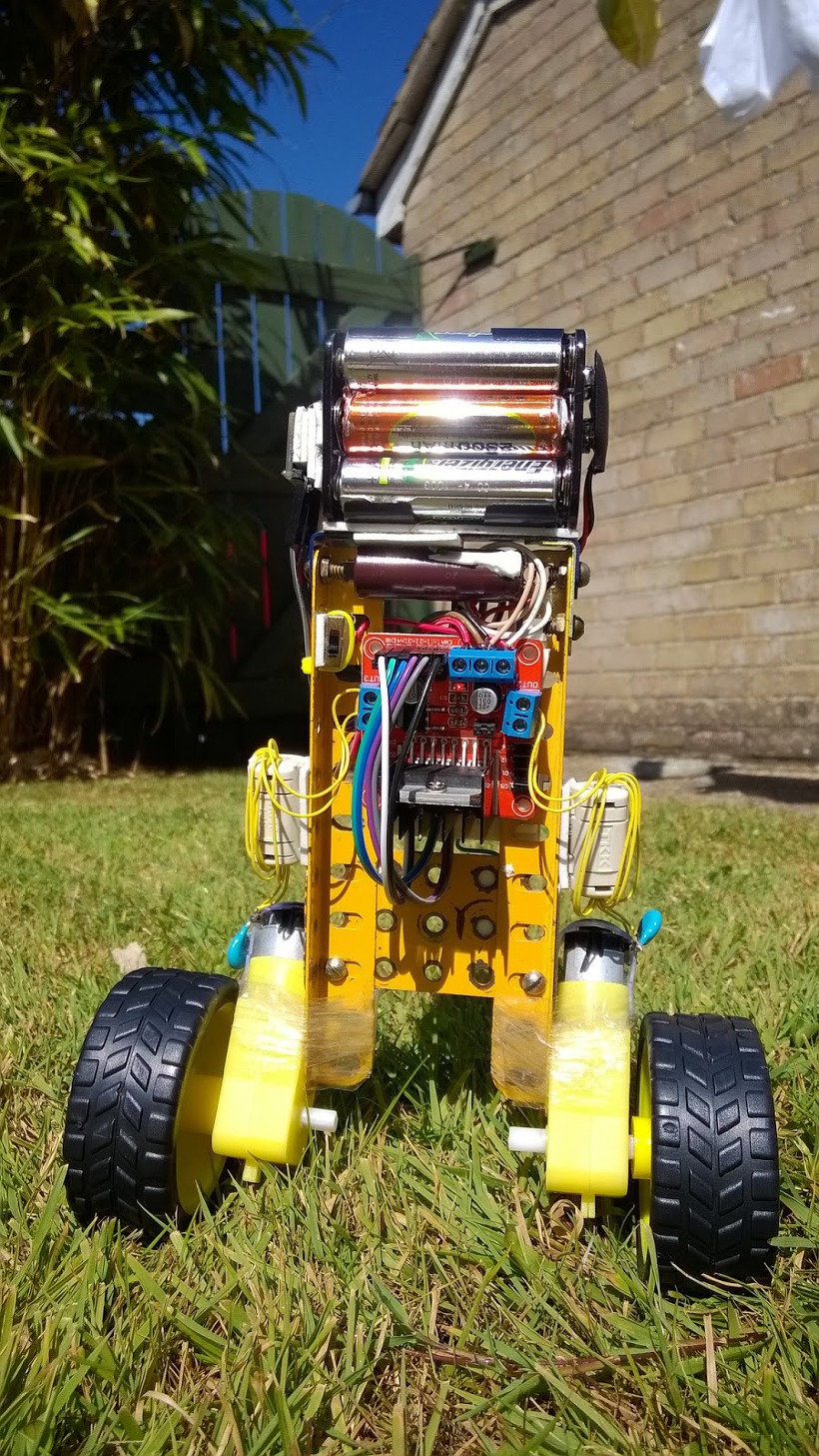

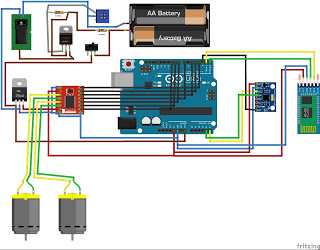

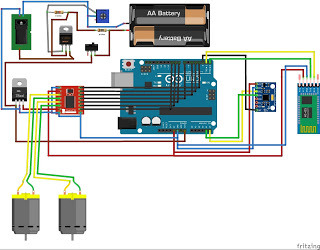

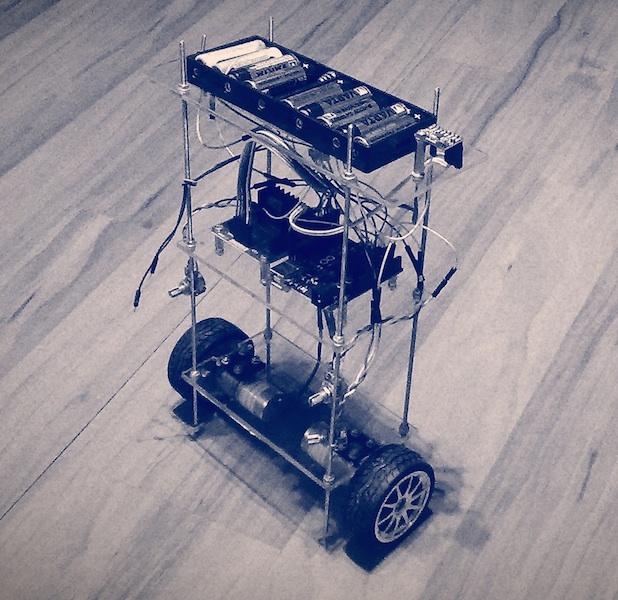

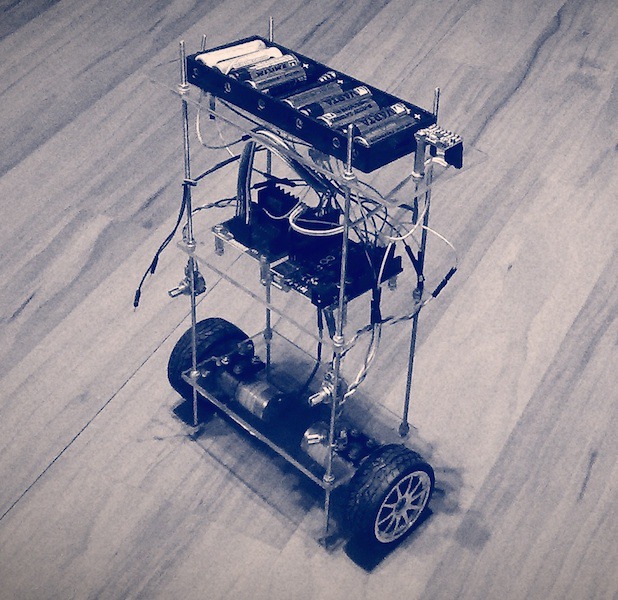

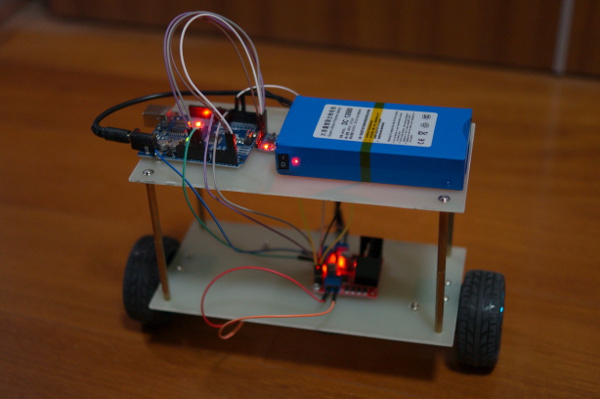

Shopping list of objects you will need.

1. Compatible Nano V3.0 – ATmega328

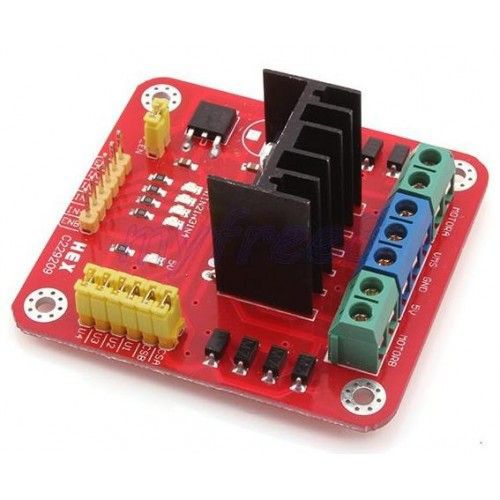

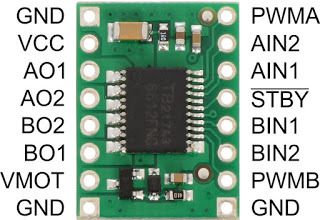

2. L298N DC Stepper Motor Dual H Bridge

4. SYB-170 Breadboard

// Most of this code is other peoples read below!!

// the bits I have hacked are indicated thusly//********************************************************************************************************************************************************

// MY STUFF

// i found PlyAlex https://www.youtube.com/watch?v=nlXqIe9-R7s not a little helpful

//

// if you get the ERROR NO LIBRARY FOUND edit sketch book location in File-> Preferences

// default location of sketch book is not where you think it is.

// Most of this code is other peoples read below!!

// the bits I have hacked are indicated thusly

//********************************************************************************************************************************************************

// MY STUFF

// i found PlyAlex https://www.youtube.com/watch?v=nlXqIe9-R7s not a little helpful

//

// if you get the ERROR NO LIBRARY FOUND edit sketch book location in File-> Preferences

// default location of sketch book is not where you think it is.

//*********************************************************************************************************************************************************

// I2C device class (I2Cdev) demonstration Arduino sketch for MPU6050 class using DMP (MotionApps v2.0)

// 6/21/2012 by Jeff Rowberg <jeff@rowberg.net>

// Updates should (hopefully) always be available at https://github.com/jrowberg/i2cdevlib

//

// Changelog:

// 2013-05-08 – added seamless Fastwire support

// – added note about gyro calibration

// 2012-06-21 – added note about Arduino 1.0.1 + Leonardo compatibility error

// 2012-06-20 – improved FIFO overflow handling and simplified read process

// 2012-06-19 – completely rearranged DMP initialization code and simplification

// 2012-06-13 – pull gyro and accel data from FIFO packet instead of reading directly

// 2012-06-09 – fix broken FIFO read sequence and change interrupt detection to RISING

// 2012-06-05 – add gravity-compensated initial reference frame acceleration output

// – add 3D math helper file to DMP6 example sketch

// – add Euler output and Yaw/Pitch/Roll output formats

// 2012-06-04 – remove accel offset clearing for better results (thanks Sungon Lee)

// 2012-06-01 – fixed gyro sensitivity to be 2000 deg/sec instead of 250

// 2012-05-30 – basic DMP initialization working

/* ============================================

I2Cdev device library code is placed under the MIT license

Copyright (c) 2012 Jeff Rowberg

Permission is hereby granted, free of charge, to any person obtaining a copy

of this software and associated documentation files (the “Software”), to deal

in the Software without restriction, including without limitation the rights

to use, copy, modify, merge, publish, distribute, sublicense, and/or sell

copies of the Software, and to permit persons to whom the Software is

furnished to do so, subject to the following conditions:

The above copyright notice and this permission notice shall be included in

all copies or substantial portions of the Software.

THE SOFTWARE IS PROVIDED “AS IS”, WITHOUT WARRANTY OF ANY KIND, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO THE WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT. IN NO EVENT SHALL THE

AUTHORS OR COPYRIGHT HOLDERS BE LIABLE FOR ANY CLAIM, DAMAGES OR OTHER

LIABILITY, WHETHER IN AN ACTION OF CONTRACT, TORT OR OTHERWISE, ARISING FROM,

OUT OF OR IN CONNECTION WITH THE SOFTWARE OR THE USE OR OTHER DEALINGS IN

THE SOFTWARE.

===============================================

*/

// I2Cdev and MPU6050 must be installed as libraries, or else the .cpp/.h files

// for both classes must be in the include path of your project

#include “I2Cdev.h”

#include “MPU6050_6Axis_MotionApps20.h”

//#include “MPU6050.h” // not necessary if using MotionApps include file

// Arduino Wire library is required if I2Cdev I2CDEV_ARDUINO_WIRE implementation

// is used in I2Cdev.h

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

#include “Wire.h”

#endif

// class default I2C address is 0x68

// specific I2C addresses may be passed as a parameter here

// AD0 low = 0x68 (default for SparkFun breakout and InvenSense evaluation board)

// AD0 high = 0x69

MPU6050 mpu;

//MPU6050 mpu(0x69); // <– use for AD0 high

/* =========================================================================

NOTE: In addition to connection 3.3v, GND, SDA, and SCL, this sketch

depends on the MPU-6050’s INT pin being connected to the Arduino’s

external interrupt #0 pin. On the Arduino Uno and Mega 2560, this is

digital I/O pin 2.

* ========================================================================= */

/* =========================================================================

NOTE: Arduino v1.0.1 with the Leonardo board generates a compile error

when using Serial.write(buf, len). The Teapot output uses this method.

The solution requires a modification to the Arduino USBAPI.h file, which

is fortunately simple, but annoying. This will be fixed in the next IDE

release. For more info, see these links:

http://arduino.cc/forum/index.php/topic,109987.0.html

http://code.google.com/p/arduino/issues/detail?id=958

* ========================================================================= */

// uncomment “OUTPUT_READABLE_QUATERNION” if you want to see the actual

// quaternion components in a [w, x, y, z] format (not best for parsing

// on a remote host such as Processing or something though)

//#define OUTPUT_READABLE_QUATERNION

// uncomment “OUTPUT_READABLE_EULER” if you want to see Euler angles

// (in degrees) calculated from the quaternions coming from the FIFO.

// Note that Euler angles suffer from gimbal lock (for more info, see

// http://en.wikipedia.org/wiki/Gimbal_lock)

//#define OUTPUT_READABLE_EULER

// uncomment “OUTPUT_READABLE_YAWPITCHROLL” if you want to see the yaw/

// pitch/roll angles (in degrees) calculated from the quaternions coming

// from the FIFO. Note this also requires gravity vector calculations.

// Also note that yaw/pitch/roll angles suffer from gimbal lock (for

// more info, see: http://en.wikipedia.org/wiki/Gimbal_lock)

#define OUTPUT_READABLE_YAWPITCHROLL

// uncomment “OUTPUT_READABLE_REALACCEL” if you want to see acceleration

// components with gravity removed. This acceleration reference frame is

// not compensated for orientation, so +X is always +X according to the

// sensor, just without the effects of gravity. If you want acceleration

// compensated for orientation, us OUTPUT_READABLE_WORLDACCEL instead.

//#define OUTPUT_READABLE_REALACCEL

// uncomment “OUTPUT_READABLE_WORLDACCEL” if you want to see acceleration

// components with gravity removed and adjusted for the world frame of

// reference (yaw is relative to initial orientation, since no magnetometer

// is present in this case). Could be quite handy in some cases.

//#define OUTPUT_READABLE_WORLDACCEL

// uncomment “OUTPUT_TEAPOT” if you want output that matches the

// format used for the InvenSense teapot demo

//#define OUTPUT_TEAPOT

#define LED_PIN 13 // (Arduino is 13, Teensy is 11, Teensy++ is 6)

bool blinkState = false;

// MPU control/status vars

bool dmpReady = false; // set true if DMP init was successful

uint8_t mpuIntStatus; // holds actual interrupt status byte from MPU

uint8_t devStatus; // return status after each device operation (0 = success, !0 = error)

uint16_t packetSize; // expected DMP packet size (default is 42 bytes)

uint16_t fifoCount; // count of all bytes currently in FIFO

uint8_t fifoBuffer[64]; // FIFO storage buffer

// orientation/motion vars

Quaternion q; // [w, x, y, z] quaternion container

VectorInt16 aa; // [x, y, z] accel sensor measurements

VectorInt16 aaReal; // [x, y, z] gravity-free accel sensor measurements

VectorInt16 aaWorld; // [x, y, z] world-frame accel sensor measurements

VectorFloat gravity; // [x, y, z] gravity vector

float euler[3]; // [psi, theta, phi] Euler angle container

float ypr[3]; // [yaw, pitch, roll] yaw/pitch/roll container and gravity vector

// packet structure for InvenSense teapot demo

uint8_t teapotPacket[14] = { ‘$’, 0x02, 0,0, 0,0, 0,0, 0,0, 0x00, 0x00, ‘\r’, ‘\n’ };

//*************************************************************************************************************************************************************************

// MY Variables

float OldP = 0; // Previous value used to calculate change in P // DELTA P

float P = 0; // Proportional component

float I = 0; // Integral just the sum of P over time

float OldI = 0; // previous value of I for calculation of Delta I

float D = 0; // Differential D = P – OldP

float bp = -60; // balance point

float pwm = 0; // value of Pulse Width Modulation to ENA ENB

long a = 0; // L298N to IN 1 to 4

long b = 0; //

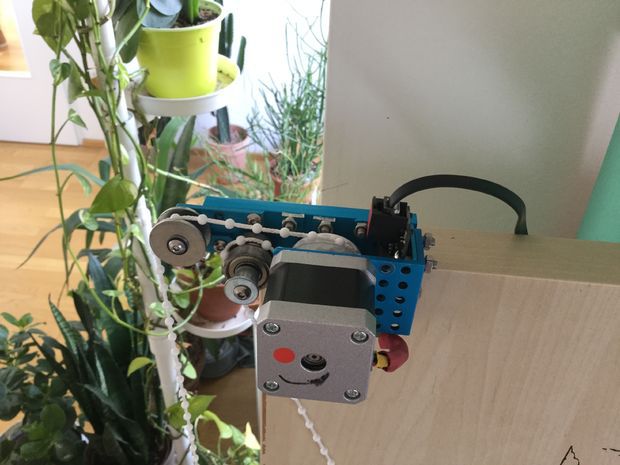

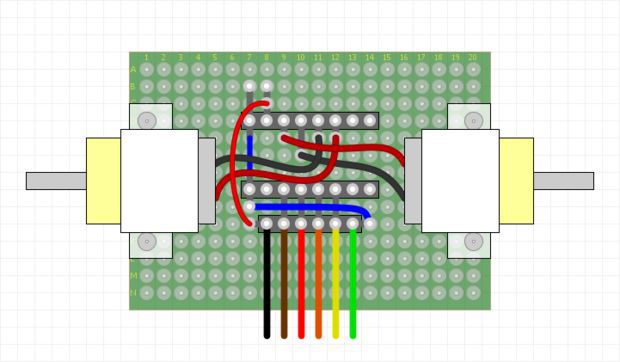

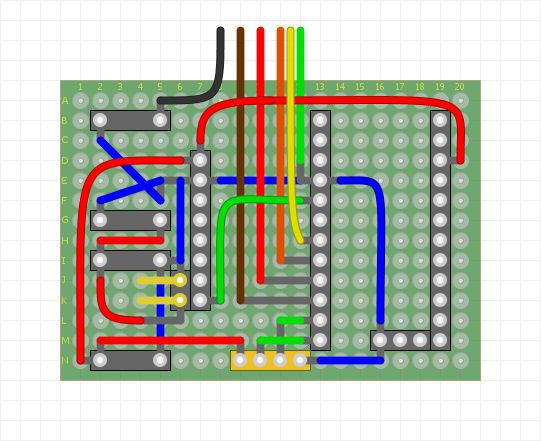

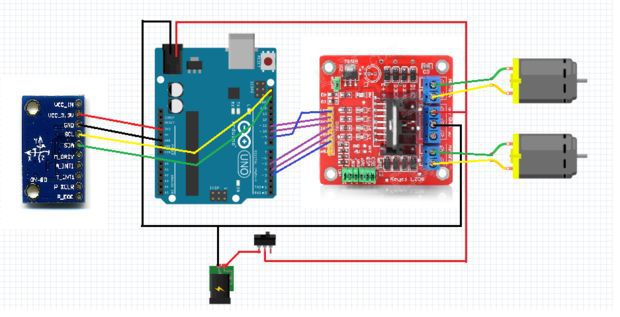

const int PinR1 = 5; // arduino pin 5 to l298 pin IN4

const int PinR2 = 6; // arduino pin 6 to l298 pin IN3

const int PinL1 = 7; // arduino pin 7 to l298 pin IN1

const int PinL2 = 8; // arduino pin 8 to l298 pin IN2

const int PwmR = 9; // arduino pin 9 to l298 pin ENB

const int PwmL = 10; // arduino pin 10 to l298 pin ENA

//****************************************************************************************************************************************************

// ================================================================

// === INTERRUPT DETECTION ROUTINE ===

// ================================================================

volatile bool mpuInterrupt = false; // indicates whether MPU interrupt pin has gone high

void dmpDataReady() {

mpuInterrupt = true;

}

// ================================================================

// === INITIAL SETUP ===

// ================================================================

void setup() {

//*********************************************************************************************************************************************************

// arduino to l298 pins hopefully self explanatory

pinMode(PinR1,OUTPUT);

pinMode(PinR2,OUTPUT);

pinMode(PinL1,OUTPUT);

pinMode(PinL2,OUTPUT);

//**********************************************************************************************************************************************************

// join I2C bus (I2Cdev library doesn’t do this automatically)

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

Wire.begin();

TWBR = 24; // 400kHz I2C clock (200kHz if CPU is 8MHz)

#elif I2CDEV_IMPLEMENTATION == I2CDEV_BUILTIN_FASTWIRE

Fastwire::setup(400, true);

#endif

// initialize serial communication

// (115200 chosen because it is required for Teapot Demo output, but it’s

// really up to you depending on your project)

Serial.begin(57600);

while (!Serial); // wait for Leonardo enumeration, others continue immediately

// NOTE: 8MHz or slower host processors, like the Teensy @ 3.3v or Ardunio

// Pro Mini running at 3.3v, cannot handle this baud rate reliably due to

// the baud timing being too misaligned with processor ticks. You must use

// 38400 or slower in these cases, or use some kind of external separate

// crystal solution for the UART timer.

// initialize device

Serial.println(F(“Initializing I2C devices…”));

mpu.initialize();

// verify connection

Serial.println(F(“Testing device connections…”));

Serial.println(mpu.testConnection() ? F(“MPU6050 connection successful”) : F(“MPU6050 connection failed”));

//****************************************************************************************************************************************

// Commented out so that program dose not wait for imput,but gets straight to work

/*

// wait for ready

Serial.println(F(“\nSend any character to begin DMP programming and demo: “));

while (Serial.available() && Serial.read()); // empty buffer

while (!Serial.available()); // wait for data

while (Serial.available() && Serial.read()); // empty buffer again

*/

//*****************************************************************************************************************************************

// load and configure the DMP

Serial.println(F(“Initializing DMP…”));

devStatus = mpu.dmpInitialize();

// supply your own gyro offsets here, scaled for min sensitivity

//****************************************************************************************************************************************

// use calibration program to get your own values

mpu.setXGyroOffset(44);//(220);

mpu.setYGyroOffset(-21);//(76);

mpu.setZGyroOffset(-30);//(-85);

mpu.setXAccelOffset(-1875);//(1788); // 1688 factory default for my test chip

mpu.setYAccelOffset(-1426);

mpu.setZAccelOffset(2215);

//****************************************************************************************************************************************

// make sure it worked (returns 0 if so)

if (devStatus == 0) {

// turn on the DMP, now that it’s ready

Serial.println(F(“Enabling DMP…”));

mpu.setDMPEnabled(true);

// enable Arduino interrupt detection

Serial.println(F(“Enabling interrupt detection (Arduino external interrupt 0)…”));

attachInterrupt(0, dmpDataReady, RISING);

mpuIntStatus = mpu.getIntStatus();

// set our DMP Ready flag so the main loop() function knows it’s okay to use it

Serial.println(F(“DMP ready! Waiting for first interrupt…”));

dmpReady = true;

// get expected DMP packet size for later comparison

packetSize = mpu.dmpGetFIFOPacketSize();

} else {

// ERROR!

// 1 = initial memory load failed

// 2 = DMP configuration updates failed

// (if it’s going to break, usually the code will be 1)

Serial.print(F(“DMP Initialization failed (code “));

Serial.print(devStatus);

Serial.println(F(“)”));

}

// configure LED for output

pinMode(LED_PIN, OUTPUT);

}

// ================================================================

// === MAIN PROGRAM LOOP ===

// ================================================================

void loop() {

// if programming failed, don’t try to do anything

if (!dmpReady) return;

// wait for MPU interrupt or extra packet(s) available

while (!mpuInterrupt && fifoCount < packetSize) {

// other program behavior stuff here

}

// reset interrupt flag and get INT_STATUS byte

mpuInterrupt = false;

mpuIntStatus = mpu.getIntStatus();

// get current FIFO count

fifoCount = mpu.getFIFOCount();

// check for overflow (this should never happen unless our code is too inefficient)

if ((mpuIntStatus & 0x10) || fifoCount == 1024) {

// reset so we can continue cleanly

mpu.resetFIFO();

Serial.println(F(“FIFO overflow!”));

// otherwise, check for DMP data ready interrupt (this should happen frequently)

} else if (mpuIntStatus & 0x02) {

// wait for correct available data length, should be a VERY short wait

while (fifoCount < packetSize) fifoCount = mpu.getFIFOCount();

// read a packet from FIFO

mpu.getFIFOBytes(fifoBuffer, packetSize);

// track FIFO count here in case there is > 1 packet available

// (this lets us immediately read more without waiting for an interrupt)

fifoCount -= packetSize;

#ifdef OUTPUT_READABLE_YAWPITCHROLL

// display Euler angles in degrees

mpu.dmpGetQuaternion(&q, fifoBuffer);

mpu.dmpGetGravity(&gravity, &q);

mpu.dmpGetYawPitchRoll(ypr, &q, &gravity);

//*********************************************************************************************************************************************************************

// My Code

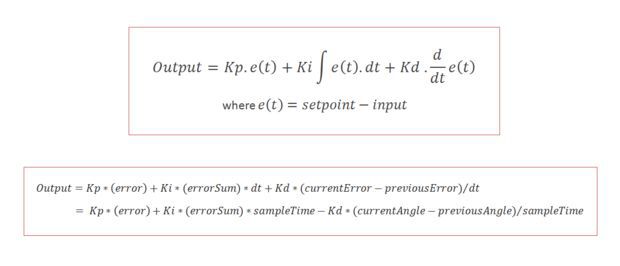

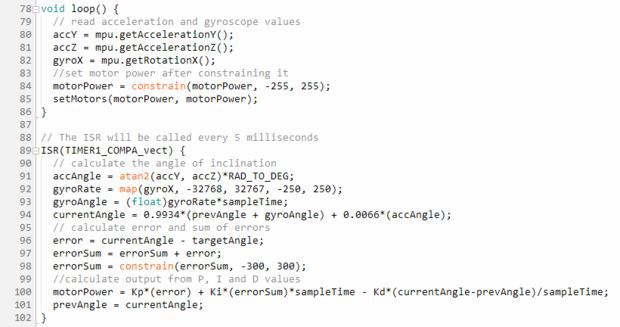

// PID control based on Pseudocode from https://en.wikipedia.org/wiki/PID_controller

// and the balance point idea from https://www.youtube.com/user/jmhrvy1947

OldP =P; // save value of P

P = (ypr[2] * 1000) + bp; // update P from MPU add bp to correct for balance

OldI = I; // save old I

I = I + (P * 0.05) ;

I = I + ((I – OldI)*2 ); // calulate new I

if( I > 250 ) I = 250; // LIMIT Stop I building up too high

if( I < -250 ) I = -250; // or too low value

D = P – OldP; // D differential change in P

pwm = ( P * 1 ) + ( I ) + ( D * 10 ) ; // P I D

a = 0;

b = 0;

if(pwm < 0){

a = 0;

b = 1;

bp = bp – 0.01;

digitalWrite(13, 0);

}

if(pwm > 0){

a = 1;

b = 0;

bp = bp + 0.01;

digitalWrite(13, 1);

}

/////////////////////////////

// remove sign from PWM as – value has no meaning

pwm = abs(pwm);

if ( pwm < 0) pwm = 0;

if ( pwm > 255) pwm = 255;

if(abs(ypr[2]) < abs(1.1)){

analogWrite(PwmR, pwm);

digitalWrite(PinR1, a);

digitalWrite(PinR2 ,b);

analogWrite(PwmL ,pwm);

digitalWrite(PinL1 ,a);

digitalWrite(PinL2 ,b);

}

else{

analogWrite(PwmR , 0);

analogWrite(PwmL , 0);

I = 0;

bp = -98;

delay(1000);

}

//********************************************************************************************************************************************************

#endif

}

}