Tag: Web Control

LED Matrix Bar Weather Station V4 – Design

LED Matrix Bar Weather Station V3 – Design

LED Matrix Bar Weather Station V2 – Design

3D Printed Humanoid Robot – Robonoid – LineUp – 20180621

[20190107] Upload Links

[20181101] Printing

[20180621] Update Design concept

[20180619] Update Design concept

[20180607] Update Design concept

[20180604] Update Design concept

[20180430] Design concept

Humanoid Robot – Robonoid – Design concept – https://youtu.be/n-flpiyNw-M

3D Design Tool: SketchUp Pro

Robonoid is small sized bipedal walking robot The robot has 17 or 19, 24 freely moveable joints and servomotor in order to provide for a range of action and stable movements. Since it’s small in size, Robonoid can balance well and cope with basic movements such as walking and getting up. Also, intricate movements like roller skating and skateboarding are possible.

Robonoid is a wireless controllable robot You can control it by WiFi protocol through your PC and Smartphones. App for android and iOS are an especially intelligible UI. By using it, complicated operations can be controlled more easily.

Robonoid is a friendly robot Robonoid was named indicates a “simply shaped robot” that everyone imagines. Robonoid was designed by pursuing a simple appearance and simple functionality.

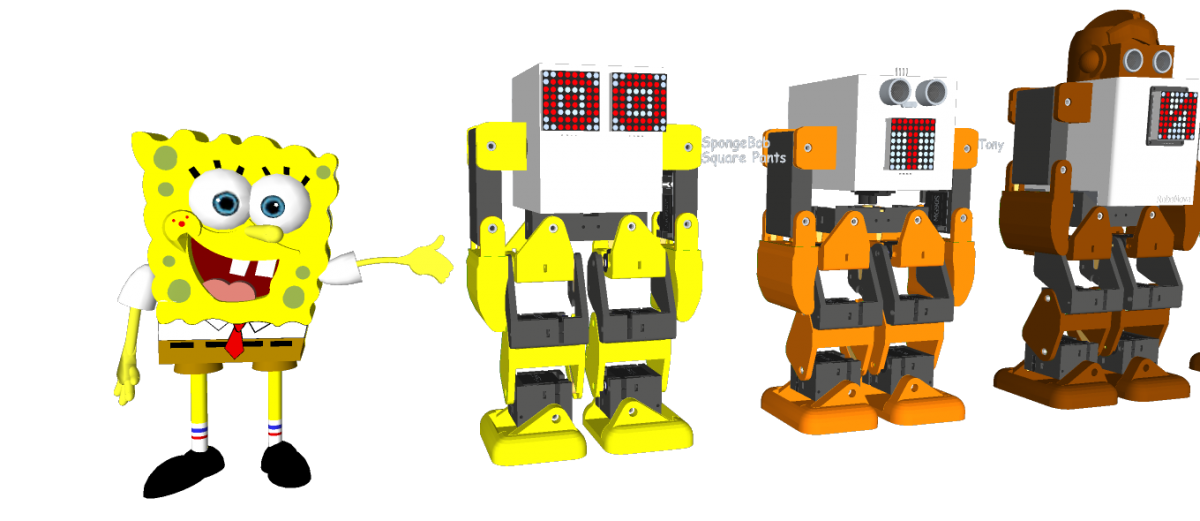

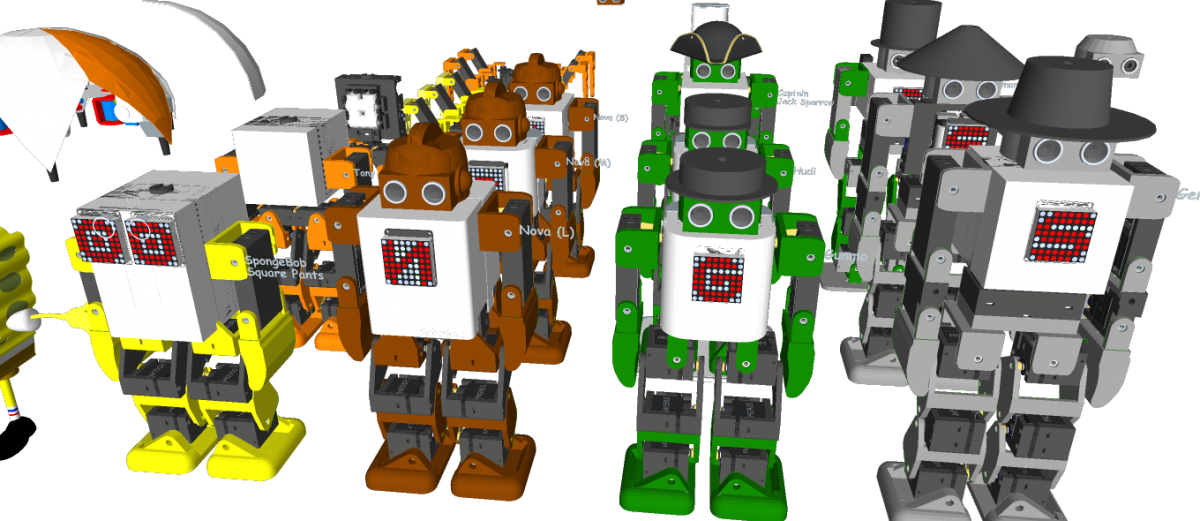

Robonoid Lineup

PSY – 135.7mm(W) x 258.39mm(H) x 100mm(D) – 17DOF

Jack – 135.7mm(W) x 305.62mm(H) x – 92,48mm(D) – 22DOF

Gentleman – 135.7mm(W) x 341.22mm(H) x – 78.5mm(D) – 22DOF

Tony – 135.7mm(W) x 265.5mm(H) x – 100mm(D) – 18DOF

SpongwBob – 135.7mm(W) x 230.0mm(H) x 100mm(D) – 16DOF

Hudi – 135.7mm(W) x 251.4mm(H) x 87mm(D) – 19DOF

Gunmo – 135.7mm(W) x 259.3mm(H) x 78.5mm(D) – 19DOF – https://youtu.be/qIZJZDcRpVw

Nova – 135.7mm(W) x 282.8mm(H) x 100mm(D) – 17DOF – https://youtu.be/kzfyKRzp_9I

Hexapod S1 – DOM 352.83mm(WD) x 193.16mm(H) – 20DOF

Robonoid is a Plen/mini-Plan/RoboHero robot derivative designed at Zalophus DesignHouse. We love the Plen2 robot but its want to new design. This is our take on a new lower cost version of the Plen2 robot using MG90S/ES08MA-II/SG90 servo’s.

The 3D printing parts were inspired by the Plen2 components, but they were redrawn from SketchUp to use the inexpensive MG90S servo motors.

Electronic Parts

1 x WeMos D1 mini ESP8266 ESP-12

1 x PCA9685 16-channel, 12-bit PWM Fm+ I2C-bus Servo controller

1 x Shield Robonoid-20CH-R0a

1 x HC-SR04 Ultrasonic Distance Measurement Sensor

2 x 16340 or 18650 Battery Holder

1 x 2S 7.4V Lithium Battery Charger Protection Board

2 x 16340 or 18650 Batteries

2 x Snap-In Single ‘A’-‘AA’ Battery Contacts 209 [KEYSTONE ELECTRONICS CORP.]

2 x Snap-In Single ‘A’-‘AA’ Battery Contacts 228 [KEYSTONE ELECTRONICS CORP.]

1 x DC Jack and Battery Harness Cable

17/19 x MG90S Metal Gear Servo Motors

3D Printing Parts

- Robonoid_BatteryBracket16340.stl ……https://pinshape.com/items/49080

- Robonoid_BatteryHolder18650.stl …..https://pinshape.com/items/49082

- Robonoid_BodyGentleman.stl ……..https://pinshape.com/items/49105

- Robonoid_BodyGunmo.stl …….https://pinshape.com/items/49100

- Robonoid_BodyHudi.stl ……https://pinshape.com/items/49098

- Robonoid_BodyNovaL.stl …….https://pinshape.com/items/49101

- Robonoid_BodySpongeBob.stl ……………”

- Robonoid_BodyNovaS.stl …..https://pinshape.com/items/49103

- Robonoid_BodyTony.stl …….https://pinshape.com/items/49102

- Robonoid_BodyTonyPants.stl ……”

- Robonoid_BodyTonyServoBracket.stl ……”

Robonoid_CapBaseball.stl ……https://pinshape.com/items/49095 - Robonoid_CapHudi.stl ………………..”

Robonoid_eYeLED5.stl ……….https://pinshape.com/items/49106

Robonoid_eYeWS2812.stl …….https://pinshape.com/items/49107

Robonoid_HatBoaterGunmo.stl ……https://pinshape.com/items/49093 - Robonoid_HatConical.stl ……………….”

- Robonoid_HatFes.stl ……………………..”

- Robonoid_HatTC.stl ……………………..”

- Robonoid_HatTop.stl …………………….”

Robonoid_Head.stl ……https://pinshape.com/items/49091

Robonoid_HeadNova.stl …….https://pinshape.com/items/49000

Robonoid_ElbowShoulderRol_Leftl.stl …….https://pinshape.com/items/49071

Robonoid_Foot_Left.stl …….https://pinshape.com/items/49057

Robonoid_FootSlim_Left.stl …….https://pinshape.com/items/49057

Robonoid_FootSimple_Left.stl ……..https://pinshape.com/items/49057

Robonoid_FootRollPitch_Left.stl …….https://pinshape.com/items/49063

Robonoid_Hand_Left.stl ……..https://pinshape.com/items/49070

Robonoid_HandWristShoulderPitchThighYawFoot_Left.stl ….https://pinshape.com/items/49072

Robonoid_Knee_Left.stl ……https://pinshape.com/items/49064

Robonoid_KneePitch_Left.stl ……..https://pinshape.com/items/49067

Robonoid_ShoulderPitch_Left.stl ……..https://pinshape.com/items/49072

Robonoid_ThighPitchHipRollNova_Left.stl ……..https://pinshape.com/items/49068

Robonoid_ThighPitchRoll_Left.stl ……https://pinshape.com/items/49063

Robonoid_Pants.stl …….https://pinshape.com/items/49105

Robonoid_PantsBottom.stl ……………”

WANT TO SUPPORT Zalophus’s DesignHouse?

The open source Humanoid Robot – Robonoid hardware and software is free and made with love. Please show your level of support with a voluntary donation.

Donate: https://www.paypal.com/cgi-bin/webscr?cmd=_s-xclick&hosted_button_id=RDN7ZGAVFS5UE

3D Printed Hexapod Robot – Robonoid – H1 – Design concept – Update – 20180621

___

Hexapod Robot – Robonoid – H1 -Design concept

___

Update design concept 20180621]

– Parts Update: pinshape: https://pinshape.com/items/26844

Update design concept 20170418]

– Parts Upload: pinshape: https://pinshape.com/items/26844

[ Upload design concept 20161001]

___

3D Printer: PANDORA DXs – DIY Desktop 3D Printer

3D Design Tool: SketchUp Pro

Robonoid is small sized bipedal walking robot

The robot has 20 freely moveable joints and servomotor in order to provide for a range of action and stable movements. Since it’s small in size, Robonoid can balance well and cope with basic movements such as walking and getting up. Also, intricate movements like roller skating and skateboarding are possible.

Robonoid is a wireless controllable robot

You can control it by WiFi protocol through your PC and Smartphones. App for android and iOS are an especially intelligible UI. By using it, complicated operations can be controlled more easily.

Robonoid is a friendly robot

Robonoid was named indicates a “simply shaped robot” that everyone imagines. Robonoid was designed by pursuing a simple appearance and simple functionality.

Robonoid Lineup

– Papi – 28DOF

– S6 – 20DOF

– S4 – 14DOF

– PSY – 135.7mm(W) x 258.39mm(H) x 100mm(D) – 17DOF

– Jack – 135.7mm(W) x 305.62mm(H) x – 92,48mm(D) – 22DOF

– Gentleman – 135.7mm(W) x 341.22mm(H) x – 78.5mm(D) – 22DOF

– Tony – 135.7mm(W) x 265.5mm(H) x – 100mm(D) – 18DOF

– SpongwBob – 135.7mm(W) x 230.0mm(H) x 100mm(D) – 16DOF

– Hudi – 135.7mm(W) x 251.4mm(H) x 87mm(D) – 19DOF

– Gunmo – 135.7mm(W) x 259.3mm(H) x 78.5mm(D) – 19DOF

– Nova – 135.7mm(W) x 282.8mm(H) x 100mm(D) – 17DOF

– M1 – 180.7mm(W) x 350.74mm(H) x 110mm(D) – 24DOF

– Hexapod H1 – DOM 352.83mm(WD) x 193.16mm(H) – 20DOF

Robonoid is a Plen/mini-Plan/RoboHero robot derivative designed at Zalophus DesignHouse. We love the Plen2 robot but its want to new design. This is our take on a new lower cost version of the Plen2 robot using ES08MA-II/SG90 servo’s.

The 3D printing parts were inspired by the Plen2 components, but they were redrawn from SketchUp to use the inexpensive MG90S servo motors.

Electronic Parts

– 1 x WeMos D1 mini ESP8266 ESP-12

– 1 x PCA9685 16-channel, 12-bit PWM Fm+ I2C-bus Servo controller

– 1 x Robonoid-20CH-R0a Shield

– 1 x HC-SR04 Ultrasonic Distance Measurement Sensor

– 2 x 16340 Battery Holder

– 1 x 2S 7.4V Lithium Battery Charger Protection Board

– 2 x 16340 Batteries

– 1 x DC Jack and Battery Harness Cable

– 20 x ES08MA-II Metal Gear Servo Motors

3D Printing Parts

– Coxa: https://pinshape.com/items/34560

– 3 x Left

– 3 x Right

– Femur: https://pinshape.com/items/34559

– 3 x Left Top

– 3 x Left Bottom

– 3 x Right Top

– 3 x Right Bottom

– Patella: https://pinshape.com/items/34558

– 3 x Left Top

– 3 x Left Bottom

– 3 x Right Top

– 3 x Right Bottom

– Tibia: https://pinshape.com/items/34556

– 3 x Left Top

– 3 x Left Bottom

– 3 x Right Top

– 3 x Right Bottom

– 6 x Tarsus: https://pinshape.com/items/34557

– Shield: https://pinshape.com/items/34561

– 6 x Top

– 6 x Bottom

– 6 x Clip Center

– 12 x Clip Side

– Body: ……………………..Working….

– 1 x Top Plate

– 1 x Bottom Plate

The open source Humanoid Robot – Robonoid hardware and software is free and made with love. Please show your level of support with a voluntary donation.

Donate:

https://www.paypal.com/cgi-bin/webscr?cmd=_s-xclick&hosted_button_id=RDN7ZGAVFS5UE

3D Printed Humanoid Robot – Robonoid – Design concept – 20180619

[20190107] Upload Links

[20181101] Printing

[20180621] Update Design concept

[20180619] Update Design concept

[20180607] Update Design concept

[20180604] Update Design concept

[20180430] Design concept

Humanoid Robot – Robonoid – Design concept – https://youtu.be/n-flpiyNw-M

3D Design Tool: SketchUp Pro

Robonoid is small sized bipedal walking robot The robot has 17 or 19, 24 freely moveable joints and servomotor in order to provide for a range of action and stable movements. Since it’s small in size, Robonoid can balance well and cope with basic movements such as walking and getting up. Also, intricate movements like roller skating and skateboarding are possible.

Robonoid is a wireless controllable robot You can control it by WiFi protocol through your PC and Smartphones. App for android and iOS are an especially intelligible UI. By using it, complicated operations can be controlled more easily.

Robonoid is a friendly robot Robonoid was named indicates a “simply shaped robot” that everyone imagines. Robonoid was designed by pursuing a simple appearance and simple functionality.

Robonoid Lineup

PSY – 135.7mm(W) x 258.39mm(H) x 100mm(D) – 17DOF

Jack – 135.7mm(W) x 305.62mm(H) x – 92,48mm(D) – 22DOF

Gentleman – 135.7mm(W) x 341.22mm(H) x – 78.5mm(D) – 22DOF

Tony – 135.7mm(W) x 265.5mm(H) x – 100mm(D) – 18DOF

SpongwBob – 135.7mm(W) x 230.0mm(H) x 100mm(D) – 16DOF

Hudi – 135.7mm(W) x 251.4mm(H) x 87mm(D) – 19DOF

Gunmo – 135.7mm(W) x 259.3mm(H) x 78.5mm(D) – 19DOF – https://youtu.be/qIZJZDcRpVw

Nova – 135.7mm(W) x 282.8mm(H) x 100mm(D) – 17DOF – https://youtu.be/kzfyKRzp_9I

Hexapod S1 – DOM 352.83mm(WD) x 193.16mm(H) – 20DOF

Robonoid is a Plen/mini-Plan/RoboHero robot derivative designed at Zalophus DesignHouse. We love the Plen2 robot but its want to new design. This is our take on a new lower cost version of the Plen2 robot using MG90S/ES08MA-II/SG90 servo’s.

The 3D printing parts were inspired by the Plen2 components, but they were redrawn from SketchUp to use the inexpensive MG90S servo motors.

Electronic Parts

1 x WeMos D1 mini ESP8266 ESP-12

1 x PCA9685 16-channel, 12-bit PWM Fm+ I2C-bus Servo controller

1 x Shield Robonoid-20CH-R0a

1 x HC-SR04 Ultrasonic Distance Measurement Sensor

2 x 16340 or 18650 Battery Holder

1 x 2S 7.4V Lithium Battery Charger Protection Board

2 x 16340 or 18650 Batteries

2 x Snap-In Single ‘A’-‘AA’ Battery Contacts 209 [KEYSTONE ELECTRONICS CORP.]

2 x Snap-In Single ‘A’-‘AA’ Battery Contacts 228 [KEYSTONE ELECTRONICS CORP.]

1 x DC Jack and Battery Harness Cable

17/19 x MG90S Metal Gear Servo Motors

3D Printing Parts

- Robonoid_BatteryBracket16340.stl ……https://pinshape.com/items/49080

- Robonoid_BatteryHolder18650.stl …..https://pinshape.com/items/49082

- Robonoid_BodyGentleman.stl ……..https://pinshape.com/items/49105

- Robonoid_BodyGunmo.stl …….https://pinshape.com/items/49100

- Robonoid_BodyHudi.stl ……https://pinshape.com/items/49098

- Robonoid_BodyNovaL.stl …….https://pinshape.com/items/49101

- Robonoid_BodySpongeBob.stl ……………”

- Robonoid_BodyNovaS.stl …..https://pinshape.com/items/49103

- Robonoid_BodyTony.stl …….https://pinshape.com/items/49102

- Robonoid_BodyTonyPants.stl ……”

- Robonoid_BodyTonyServoBracket.stl ……”

Robonoid_CapBaseball.stl ……https://pinshape.com/items/49095 - Robonoid_CapHudi.stl ………………..”

Robonoid_eYeLED5.stl ……….https://pinshape.com/items/49106

Robonoid_eYeWS2812.stl …….https://pinshape.com/items/49107

Robonoid_HatBoaterGunmo.stl ……https://pinshape.com/items/49093 - Robonoid_HatConical.stl ……………….”

- Robonoid_HatFes.stl ……………………..”

- Robonoid_HatTC.stl ……………………..”

- Robonoid_HatTop.stl …………………….”

Robonoid_Head.stl ……https://pinshape.com/items/49091

Robonoid_HeadNova.stl …….https://pinshape.com/items/49000

Robonoid_ElbowShoulderRol_Leftl.stl …….https://pinshape.com/items/49071

Robonoid_Foot_Left.stl …….https://pinshape.com/items/49057

Robonoid_FootSlim_Left.stl …….https://pinshape.com/items/49057

Robonoid_FootSimple_Left.stl ……..https://pinshape.com/items/49057

Robonoid_FootRollPitch_Left.stl …….https://pinshape.com/items/49063

Robonoid_Hand_Left.stl ……..https://pinshape.com/items/49070

Robonoid_HandWristShoulderPitchThighYawFoot_Left.stl ….https://pinshape.com/items/49072

Robonoid_Knee_Left.stl ……https://pinshape.com/items/49064

Robonoid_KneePitch_Left.stl ……..https://pinshape.com/items/49067

Robonoid_ShoulderPitch_Left.stl ……..https://pinshape.com/items/49072

Robonoid_ThighPitchHipRollNova_Left.stl ……..https://pinshape.com/items/49068

Robonoid_ThighPitchRoll_Left.stl ……https://pinshape.com/items/49063

Robonoid_Pants.stl …….https://pinshape.com/items/49105

Robonoid_PantsBottom.stl ……………”

WANT TO SUPPORT Zalophus’s DesignHouse?

The open source Humanoid Robot – Robonoid hardware and software is free and made with love. Please show your level of support with a voluntary donation.

Donate: https://www.paypal.com/cgi-bin/webscr?cmd=_s-xclick&hosted_button_id=RDN7ZGAVFS5UE

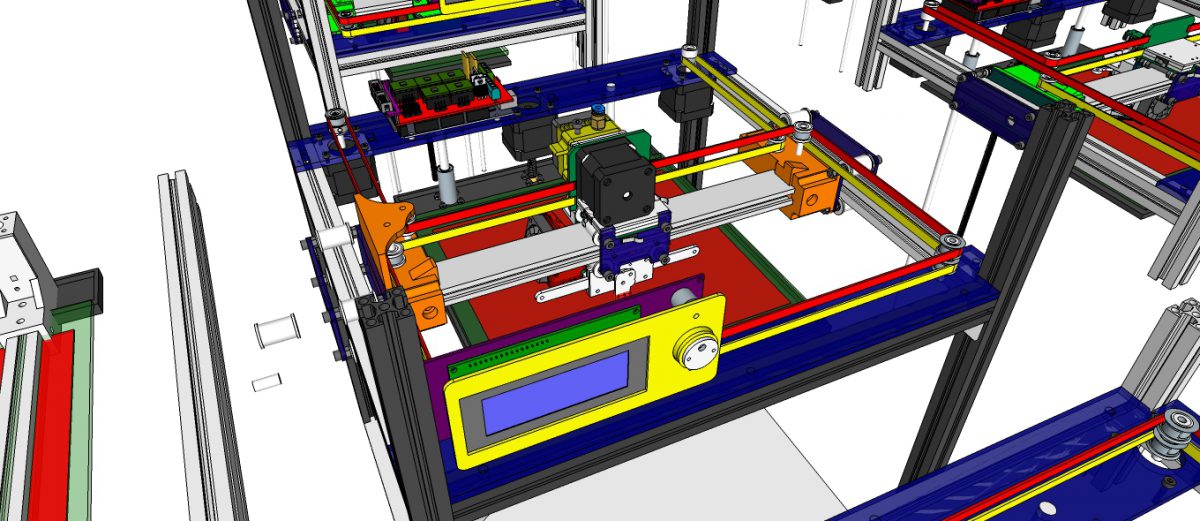

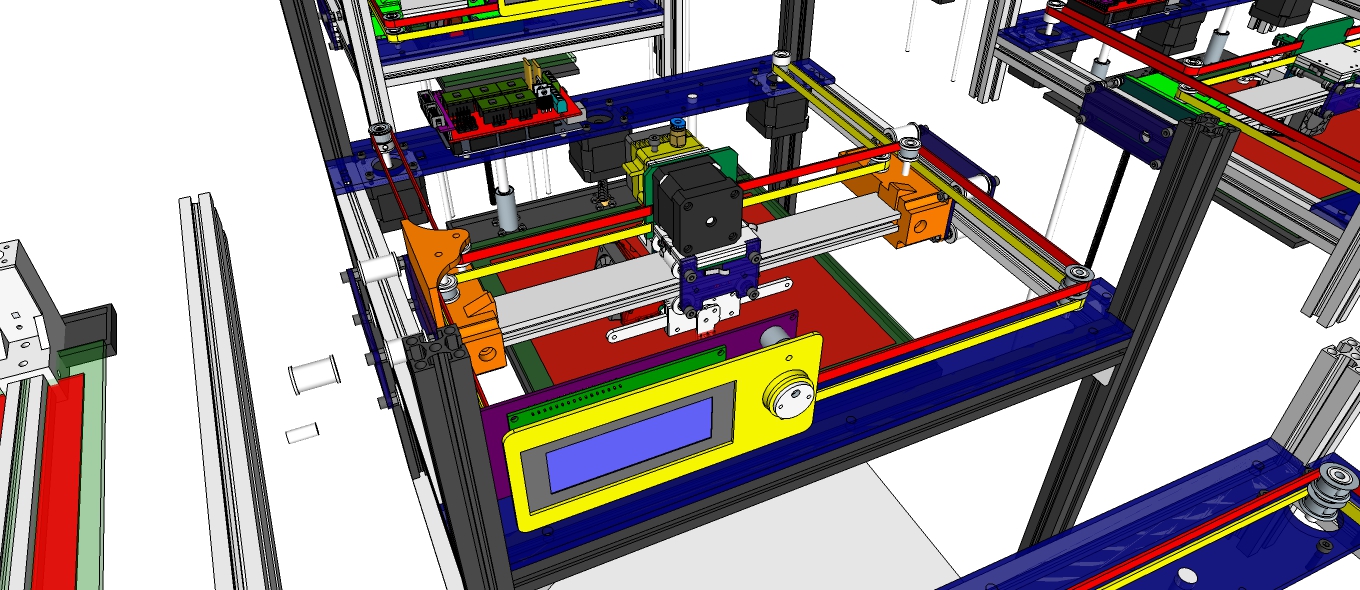

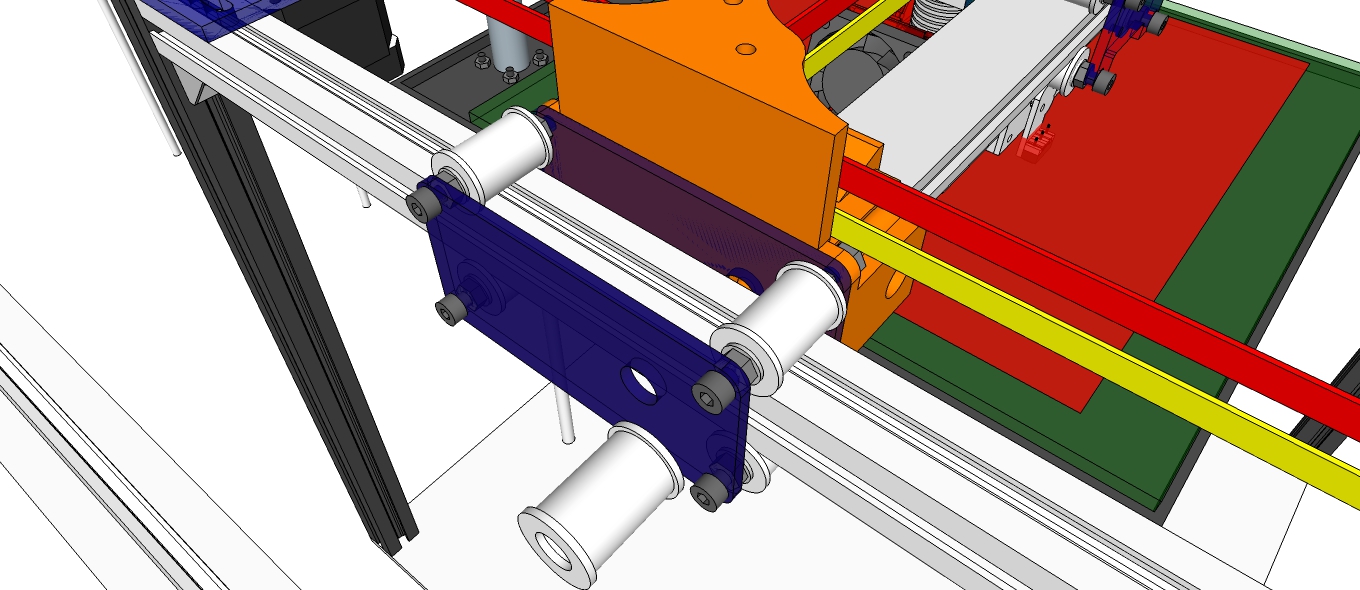

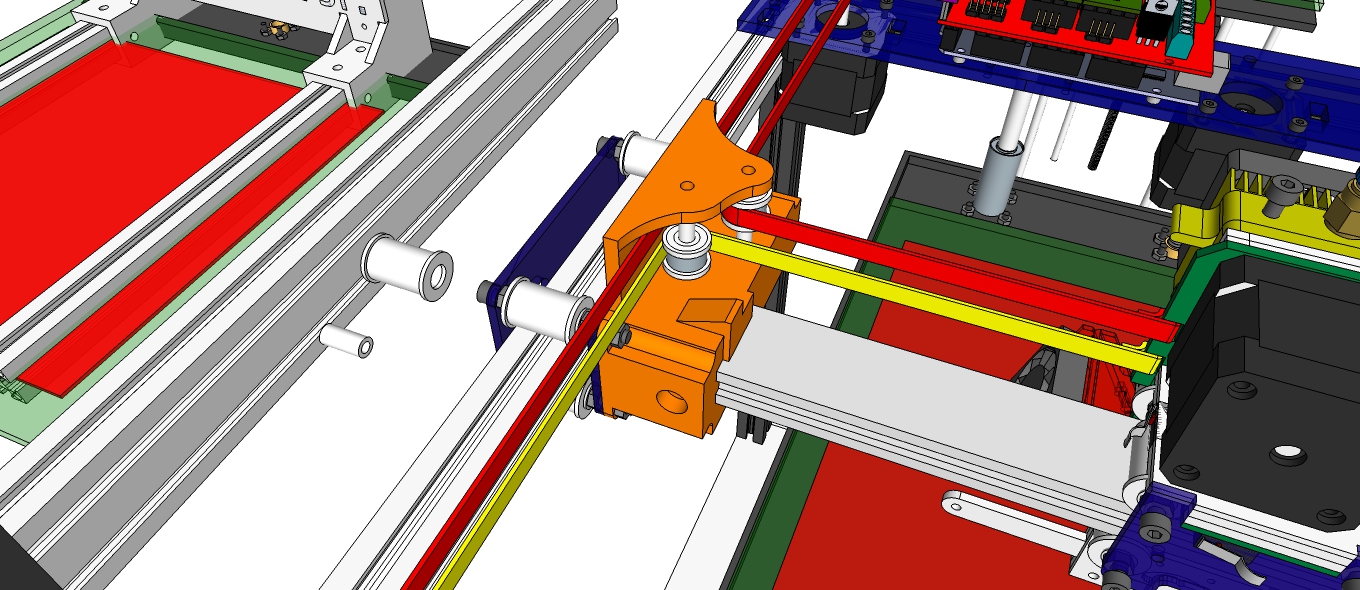

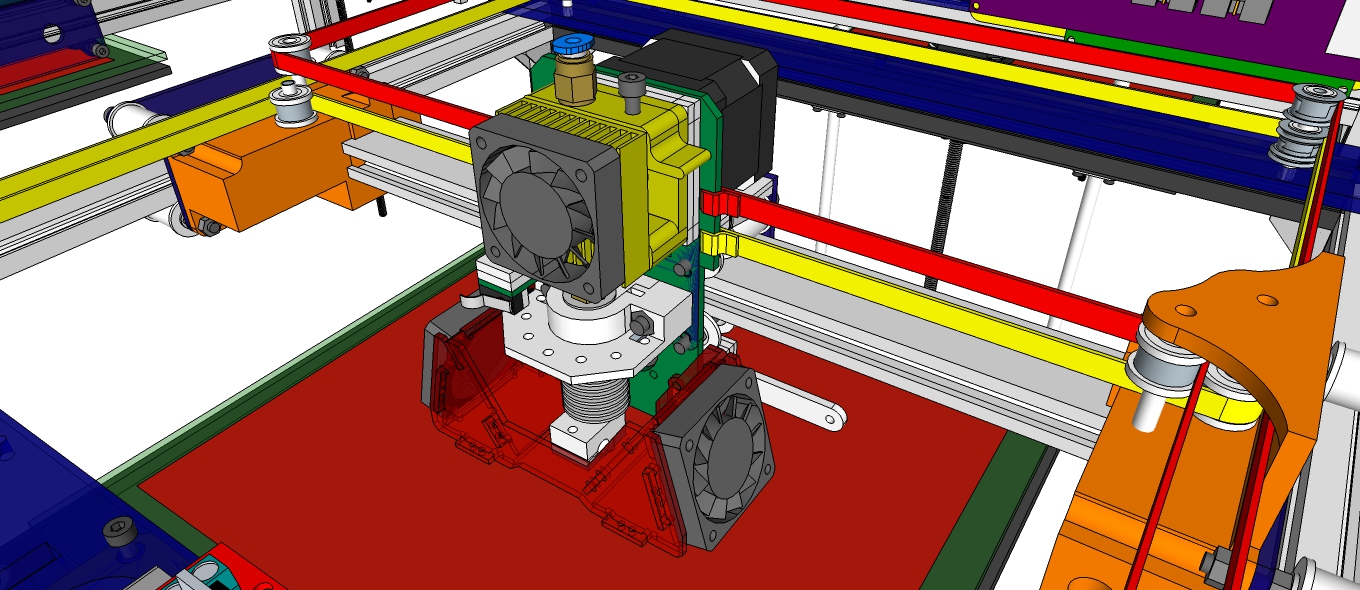

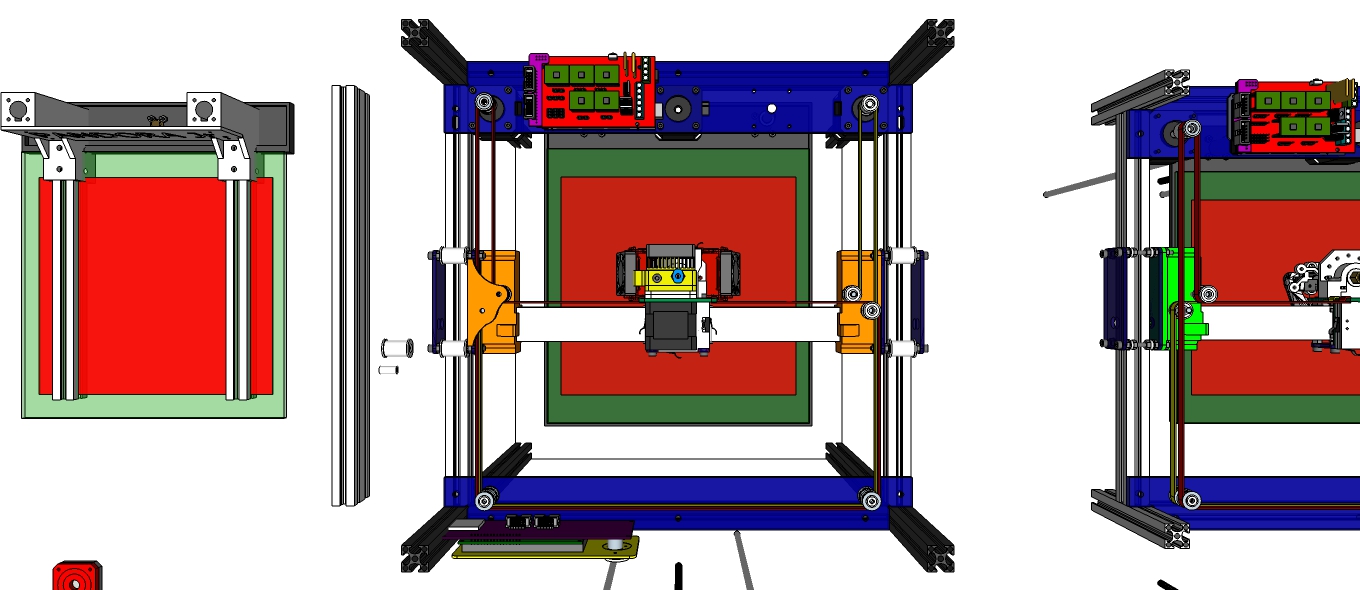

PANDORA Junior DXs – 3D Design Concept

DIY 3D Printer – PANDORA Junior DXs (Design eXtreme single)

3D Design Tool: SketchUp Pro

Technical Specifications

Printing

Technology: FFF(Fused Filament Fabrication) / CoreXY

Build Volume: 223 (W) x 207 (D) x 250 (H) mm – Heatbed

Layer Resolution: 50 ~ 200 microns

Filament: ABS or PLA, Nyron, HIPS, PVA… 1.75 mm diameter

Nozzle Diameter: 0.4 mm (0.2mm, 0.3mm, 0.8mm)

Print File Type: .Code, .STL

Layer Resolutions:

- Fast: 200 micron (0.2 mm)

- Normal: 100 micron (0.1 mm)

- hHigh: 0.06 micron (0.06 mm)

- Ultra High: 0,04 micron (0.04 mm)

Size and Weight

Product Dimensions: 410 (W) x 410 (D) x 485 (H) mm

Product Weight: 11 kg(?)

Software

Software Bundle: Cura, Slic3r, KISSlicer / Octoprint, Printrun, Repetier-Host, MatterControl

Supported File Types: .STL, .OBJ, .AMF, .Gcode

Operating Systems: All (Web-based): Windows, Mac OS, Linux

Firmware

Arduino: Modified Marlin v1.0.2-2

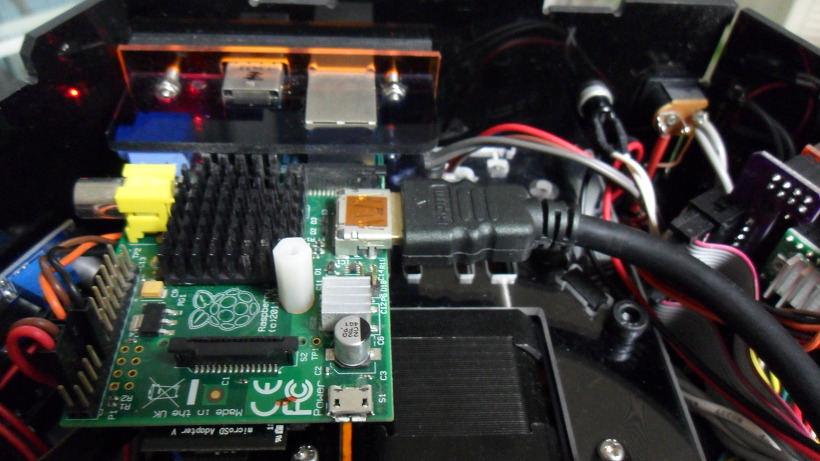

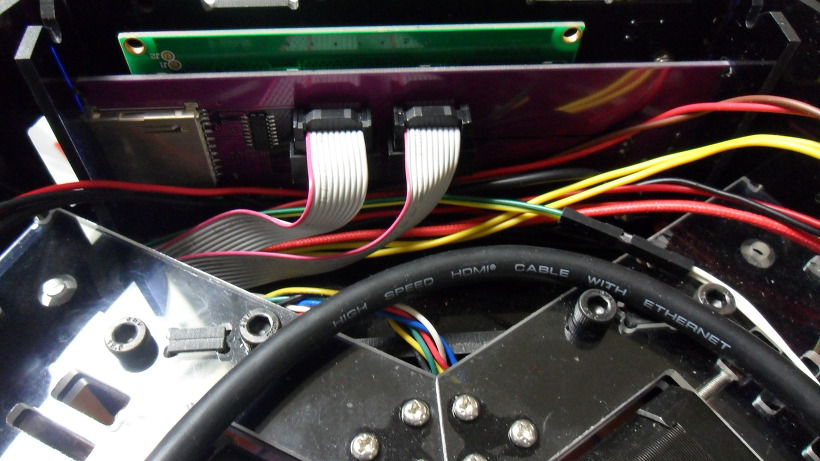

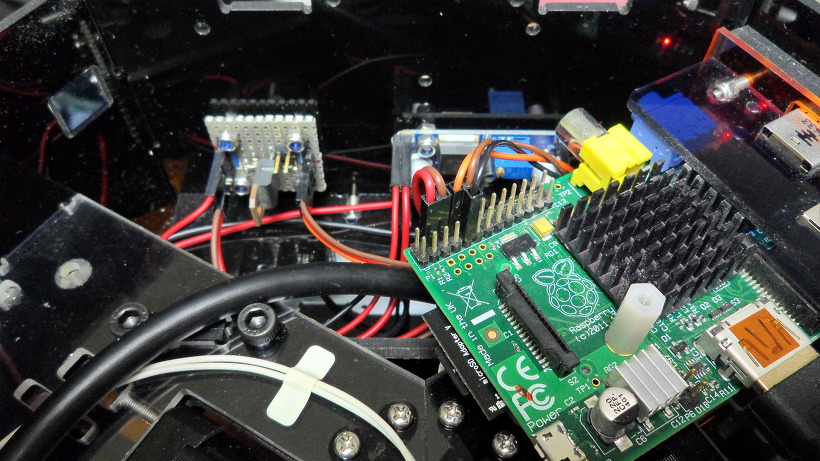

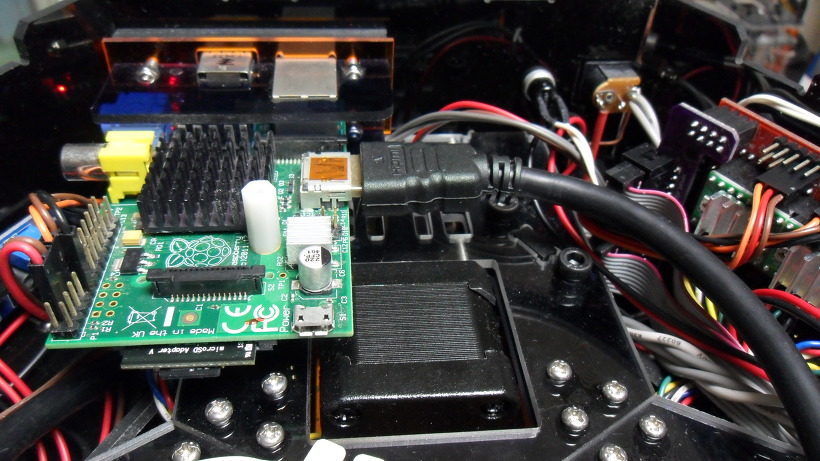

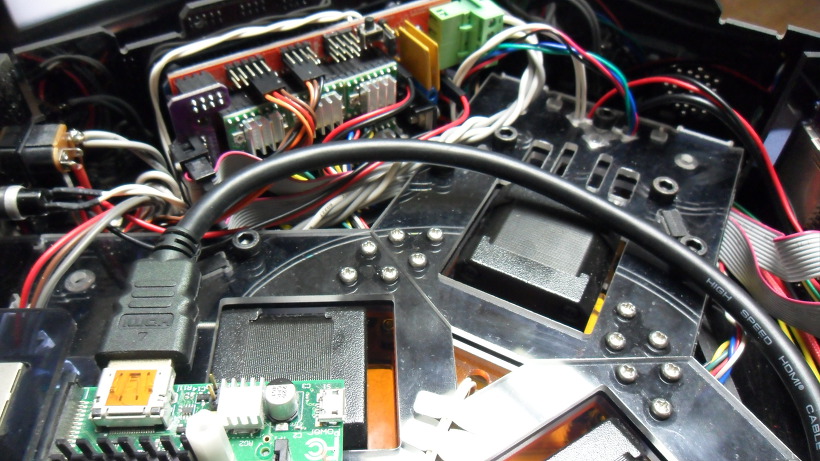

Raspberry Pi: Rasbian, Octoprint, SSH, Samba, VNC, WiringPi

Hardware

Base Plate: Profile DRF 2020, Acrylic

Step Motor: NEMA 17 – Phase: 4, Step Angle: 1.8 Deg/Step, Holding Torque: 2.6Kg.cm

- X/Y/Z/E – 4EA

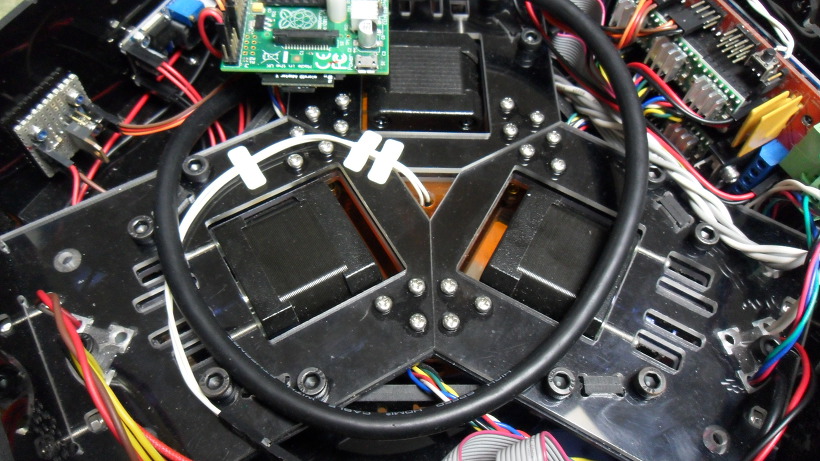

Cartesian (xyz): X/Y Head: Profile DRF 2020, Z Bed: 10mm Linear Shaft and 8D Screw Rod

Electrical

Control Board: Arduino Mega 2560

Control Shield: Ramps 1.4 Board

Display Board: Reprap Discount Smart Controller LCD 2004

Raspberry Pi: Raspberry Pi 2/3

Camera: Raspberry Camera

Power Requirements: AC 100 – 240 V, 1.4 Amps, 50-60 Hz, 220 W

Connectivity: USB, SD Card, Wi-Fi (Web-based)

Temperature:

- Nozzle temperature: 170 – 270

- Heated bed temperature: 50 – 100

- Operational temperature: 10 – 40

- Storage temperature: 0 – 32

Thanks for watching!……..Coming soon!……..Updating……

Blog:

http://zddh.blogspot.kr/2017/12/pandora-junior-dxs-3d-design-concept.html

The open source PANDORA DXs hardware and software is free and made with love. Please show your level of support with a voluntary donation.

Donate:

https://www.paypal.com/cgi-bin/webscr?cmd=_s-xclick&hosted_button_id=RDN7ZGAVFS5UE

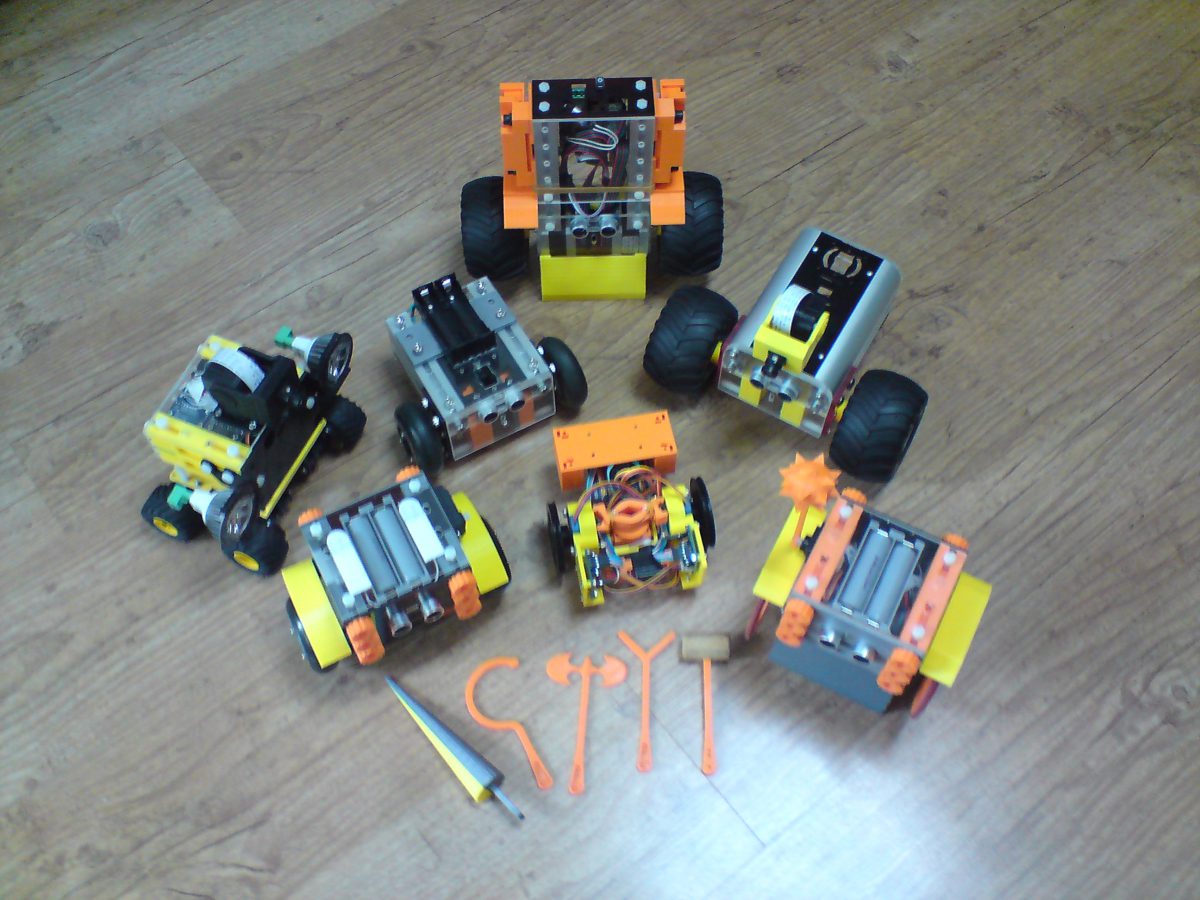

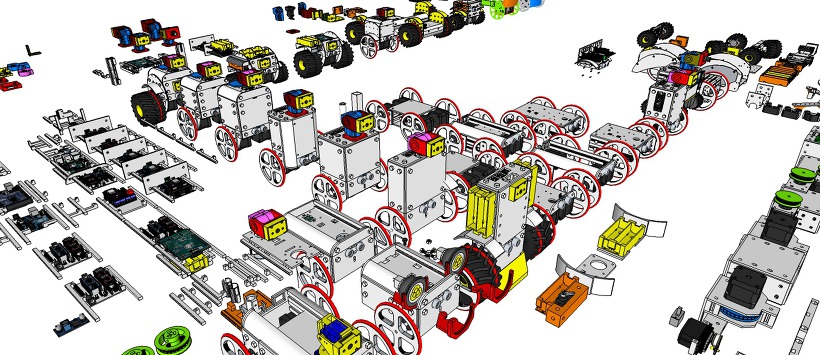

ProfileBlock™ – DIY Robot Platform – Design Concepts

[ Upload design concept 20170418]

ProfileBlock – DIY Robots & Rover & RC & Etc. Platform

3D Design Tool: SketchUp Pro

ProfileBlock’s robots are built on top of an open source Arduino-based(with ESP8266, Raspberry Pi) platform.

-

- drawBot: Drawing Robot (Polargraph, Pen, …

- Rover

Self Balancing Robot (eX-Robot, B-Robot, Roverbot, …

- RC Car

- Drone

- Scara Arm

- Arm Robot

- XY Plot

- 3D Printer

- HomeIoT

- Etc…

Hardware

Base Plate(Parts):

- Profile DF 2020

- Profile DRF 2020

- Acrylic Plate

- 3D Printing Parts

Step Motor:

- NEMA 17 – Phase: 4, Step Angle: 1.8 Deg/Step, Holding Torque: 2.6Kg.cm

- 28BYJ-48

Servo:

- Standard Servo

- SG90 Servo

Electrical

Control Board:

- Arduino

- ESP8266

- Raspberry Pi

Power Requirements:

- 4.2DVC

- 8.4VDC

- 12 VDC

Battery:

- 18650 x 2ea

- 16340 x 2ea

The open source ProfileBlock hardware and software is free and made with love. Please show your level of support with a voluntary donation.

Donate:

https://www.paypal.com/cgi-bin/webscr?cmd=_s-xclick&hosted_button_id=RDN7ZGAVFS5UE

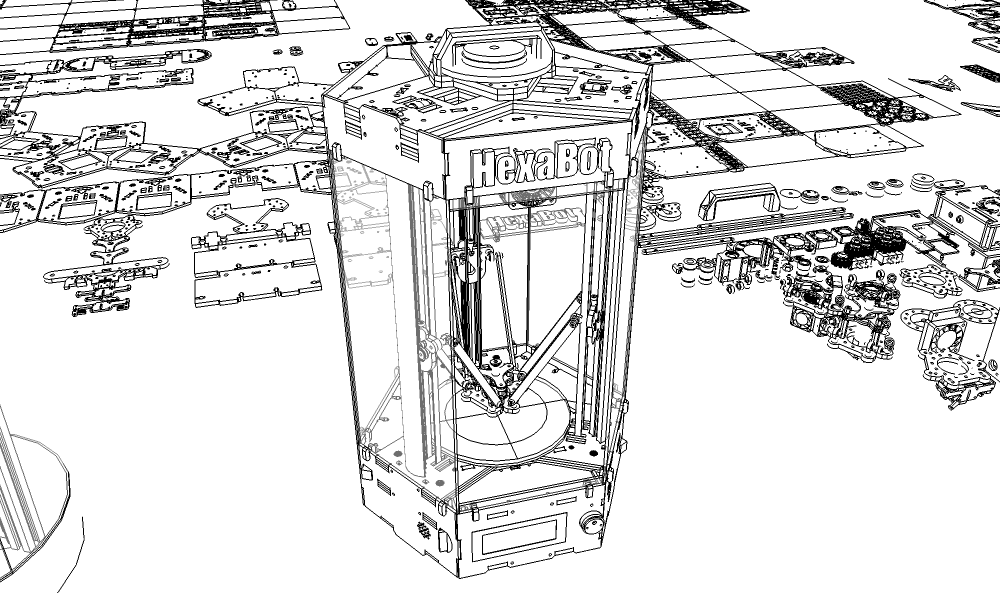

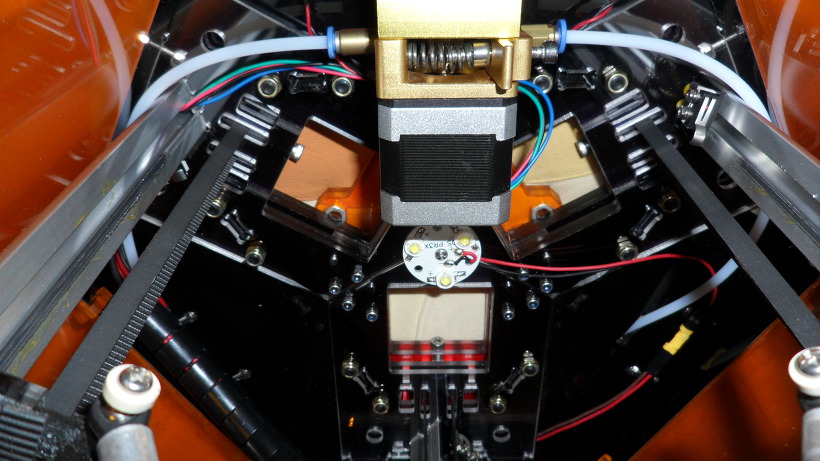

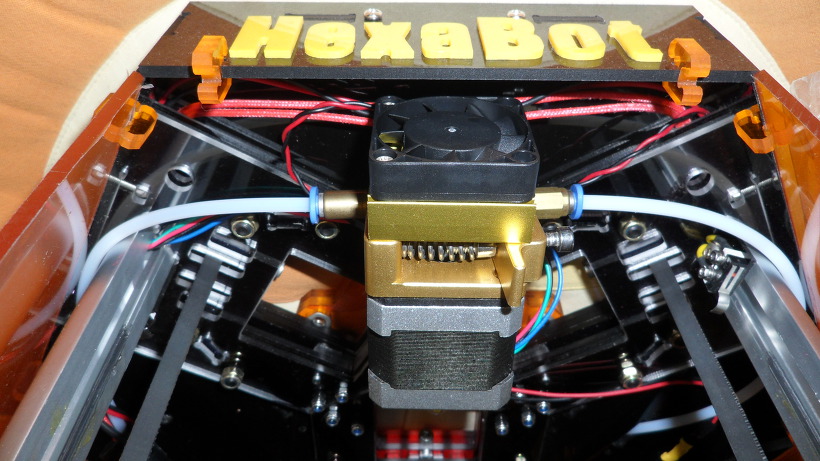

DIY Delta 3D Printer – HexaBot

DIY Delta 3D Printer – HexaBot

3D Design Tool: SketchUp Pro

Technical Specifications

Printing

Technology: FFF(Fused Filament Fabrication) / Delta

Build Volume: 95 (W) x 95 (D) x 135 (H) mm

- Auto running Heatbed

Layer Resolution: 50-200 microns

Filament: ABS or PLA, Nyron, HIPS, PVA… 1.75 mm diameter

Nozzle Diameter: 0.4 mm (0.2mm, 0.3mm, 0.8mm)

Print File Type: .Gcode, .STL

Layer Resolutions: - Fast: 200 micron (0.2 mm)

- Normal: 100 micron (0.1 mm)

- hHigh: 0.06 micron (0.06 mm)

- Ultra High: 0,04 micron (0.04 mm)

Size and Weight

Product Dimensions: 260 (W) x 300 (D) x 460 (H) mm

Product Weight: 4.5 kg

Software

Software Bundle: Cura, Slic3r, KISSlicer / Octoprint, Printrun, Repetier-Host, MatterControl

Supported File Types: .STL, .OBJ, .AMF, .Gcode

Operating Systems: All (Web-based): Windows, Mac OS, Linux

Firmware

Arduino: Modified Marlin v1.0.0

Raspberry Pi: Rasbian, Octoprint, SSH, Samba, VNC, WiringPi

Hardware

Base Plate: Profile DRF 2020, Acrylic

Step Motor: NEMA 17 – Phase: 4, Step Angle: 1.8 Deg/Step, Holding Torque: 2.6Kg.cm

- X/Y/Z/E – 4EA

Cartesian (xyz): X/Y Head: LM Guide, Z Bed: 10mm Linear Shaft and 8D Screw Rod

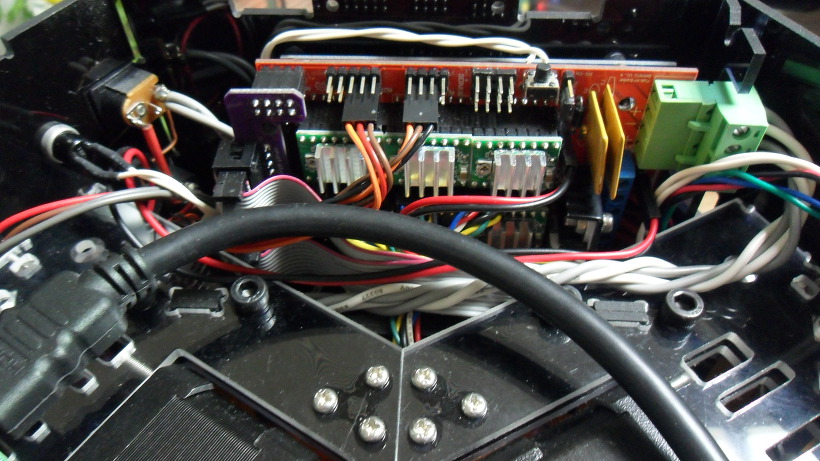

Electrical

Control Board: Arduino Mega 2560

Control Shield: Ramps 1.4 Board

Display Board: Reprap Discount Smart Controller LCD 2004

Raspberry Pi: Raspberry Pi B

Power Requirements: AC 100 – 240 V, 50-60 Hz, 12 VDC, 4.5A, 54 W

Connectivity: USB, SD Card, Wi-Fi (Web-based)

Temperature: - Nozzle temperature: 170 – 270

- Heated bed temperature: 50 – 100

- Operational temperature: 10 – 40

- Storage temperature: 0 – 32

https://www.thingiverse.com/thing:917729

Thanks for watching!…….coming soon!……Updating……

The open source HexaBot hardware and software is free and made with love. Please show your level of support with a voluntary donation.

Donate:

https://www.paypal.com/cgi-bin/webscr?cmd=_s-xclick&hosted_button_id=RDN7ZGAVFS5UE