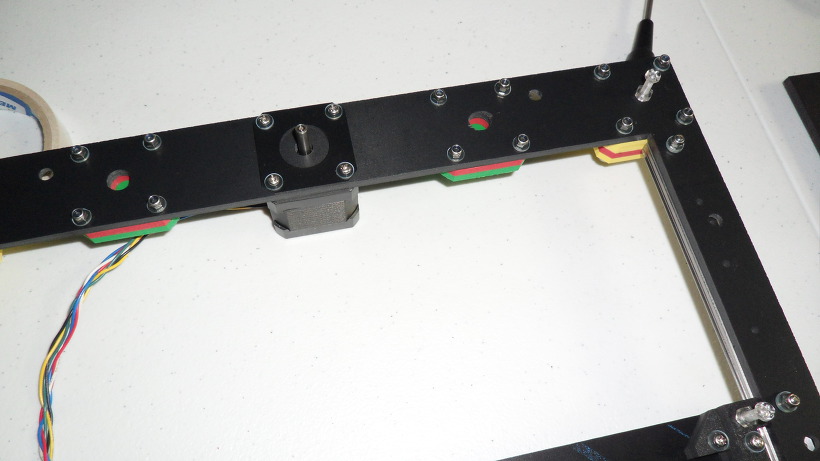

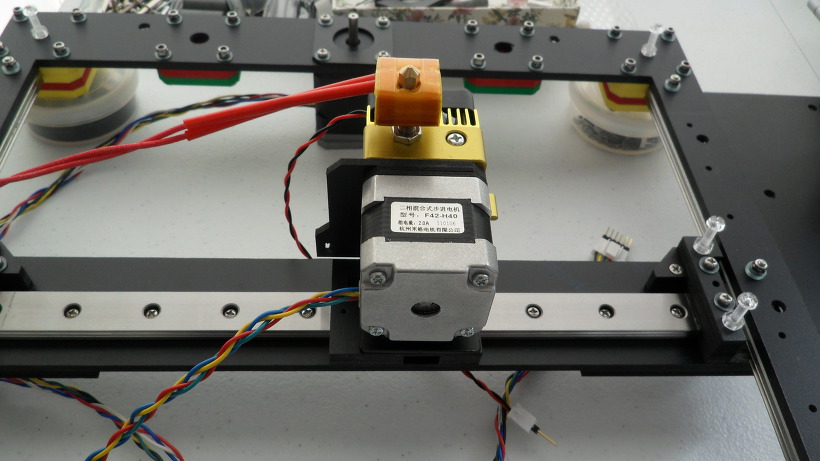

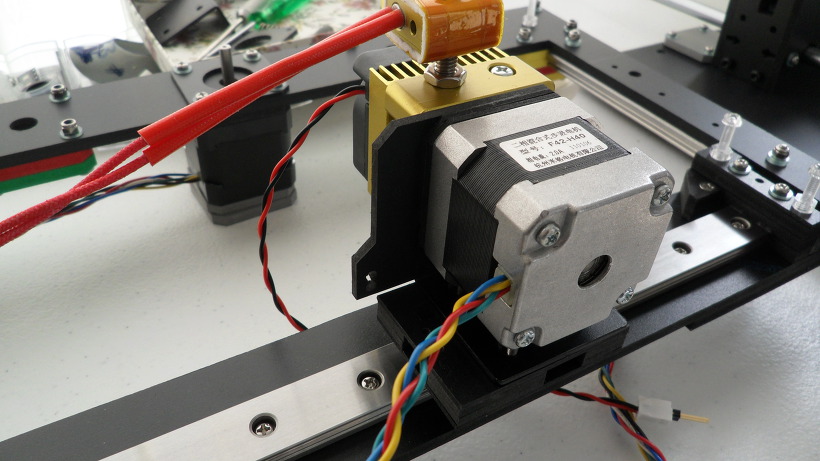

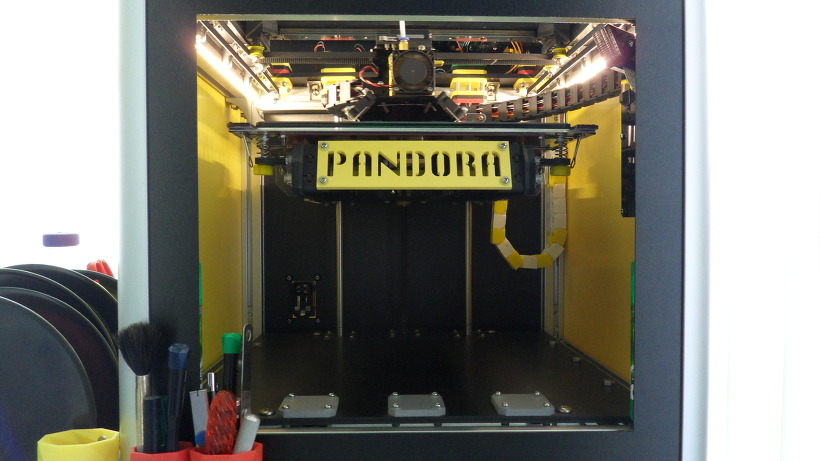

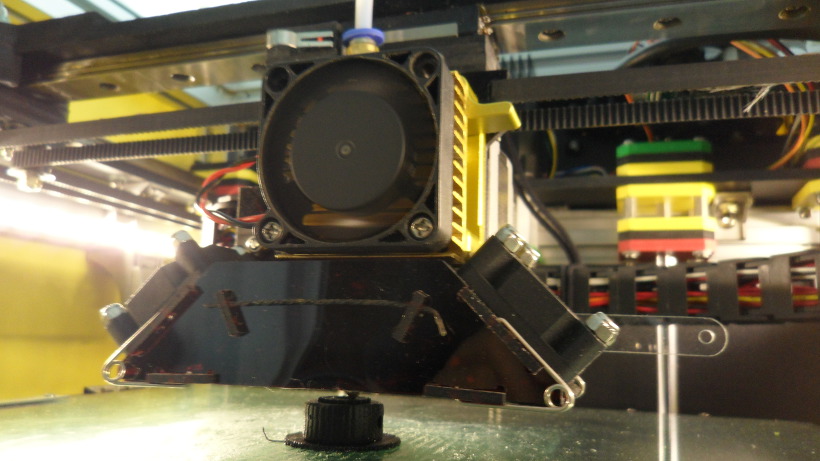

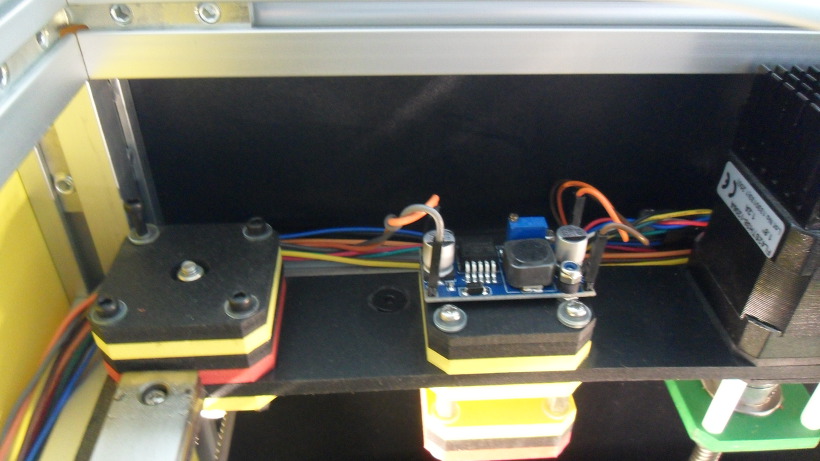

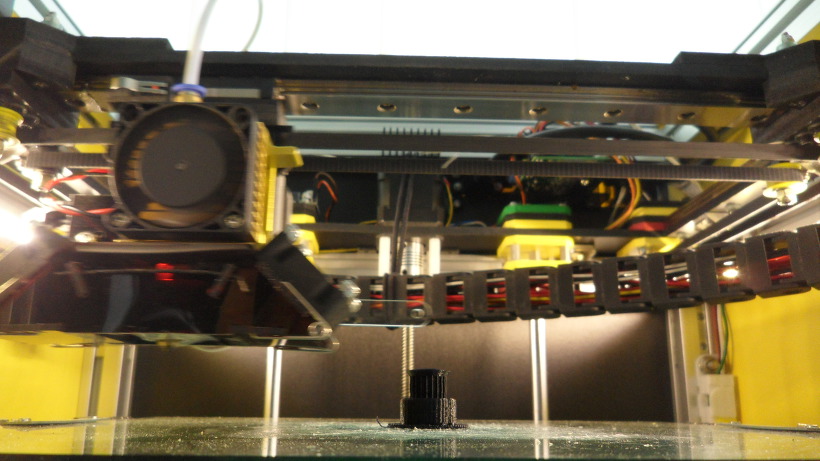

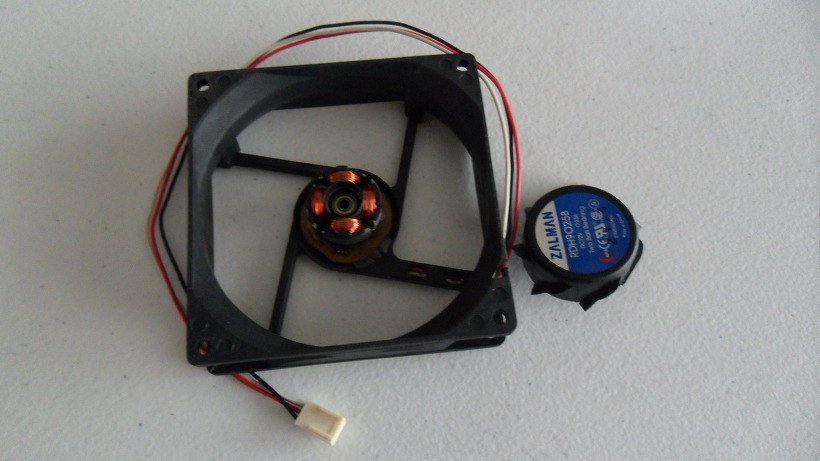

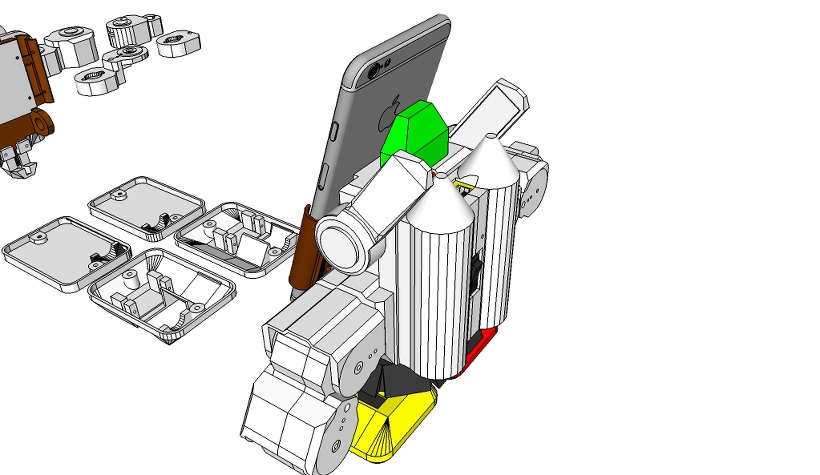

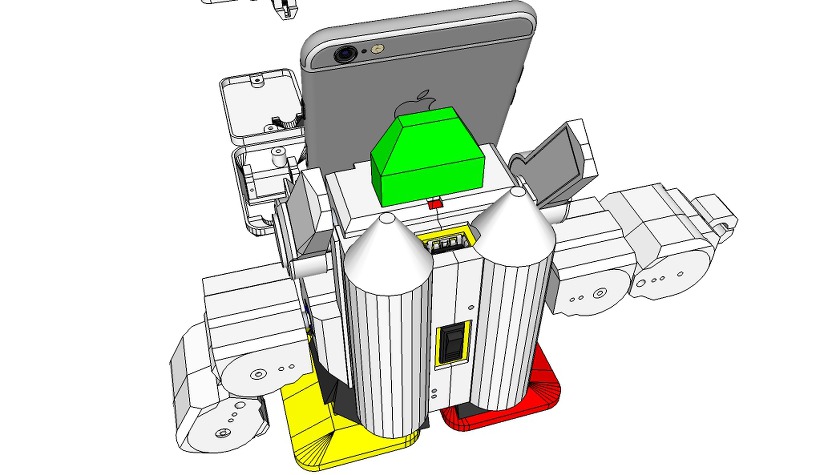

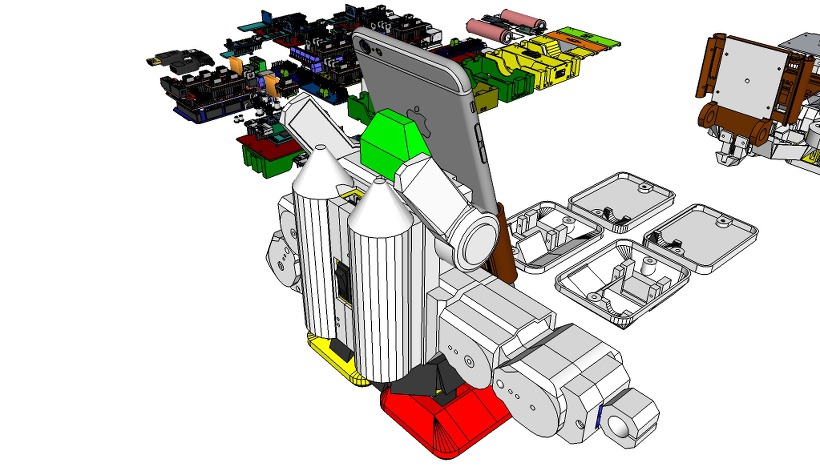

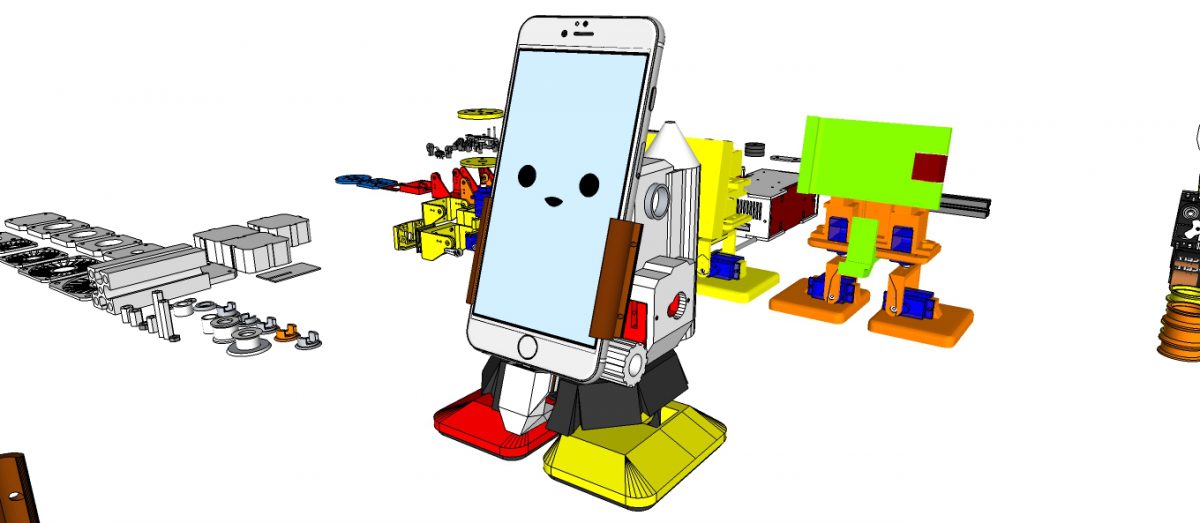

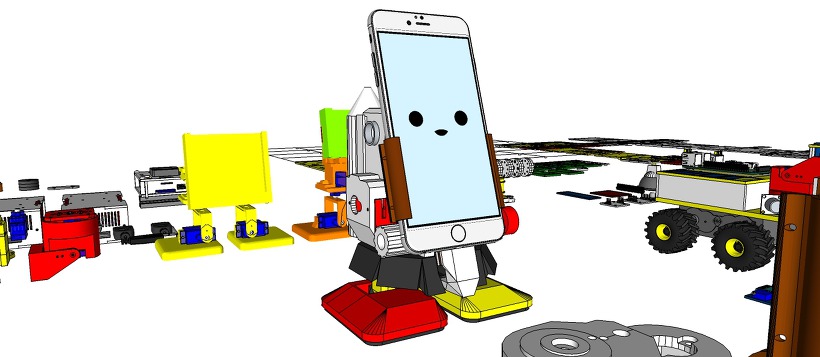

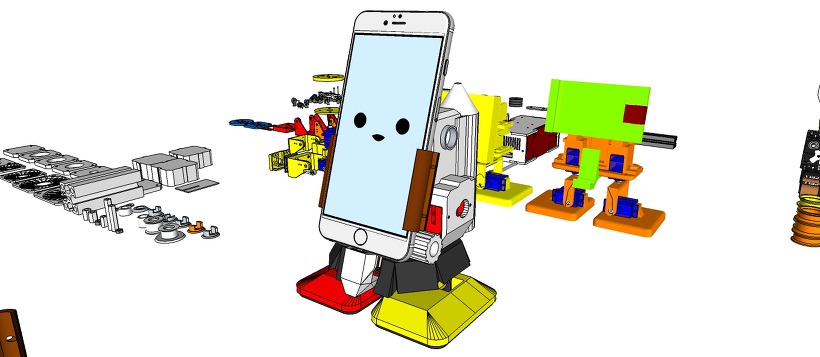

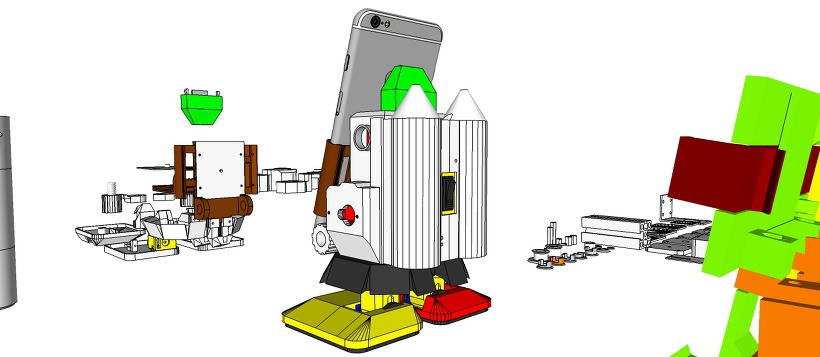

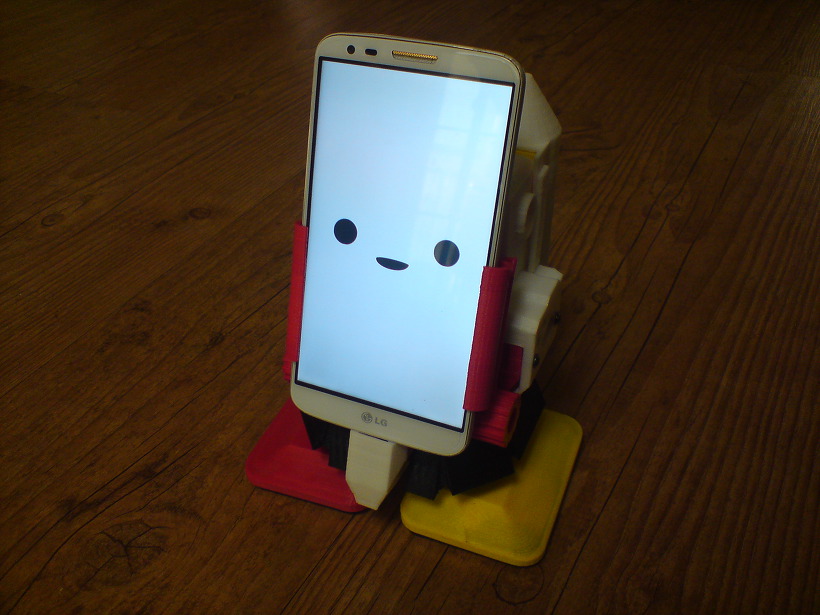

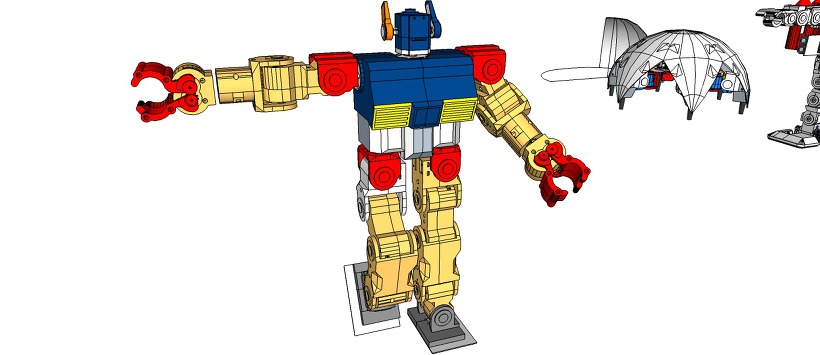

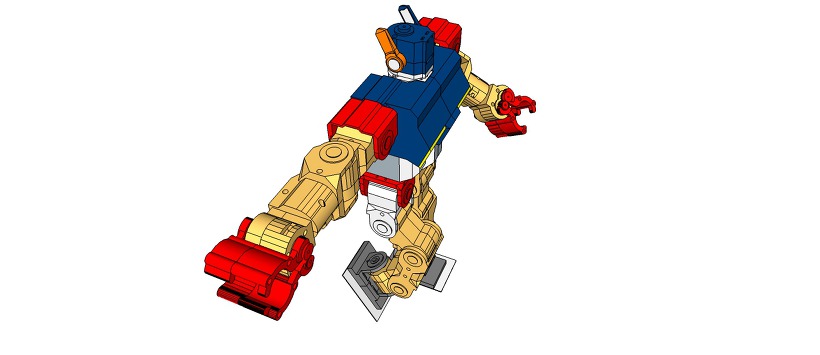

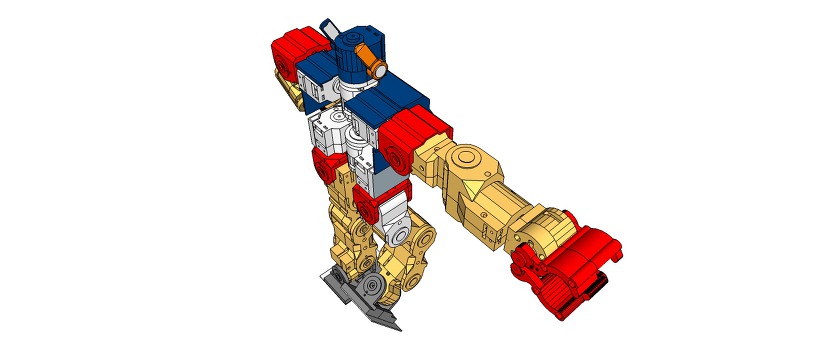

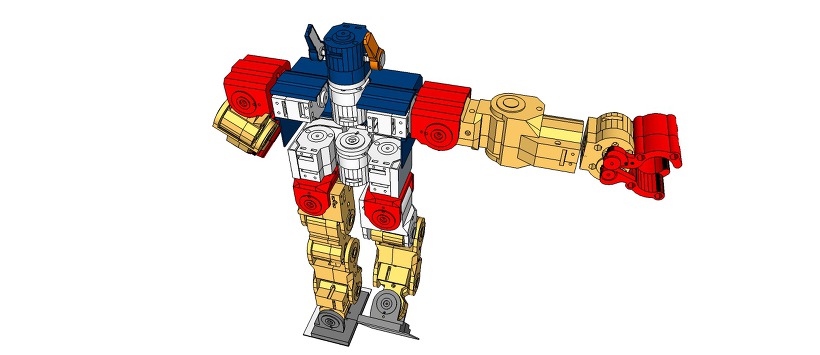

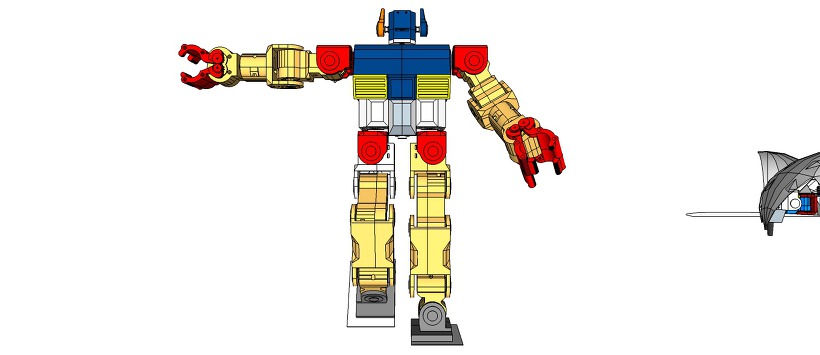

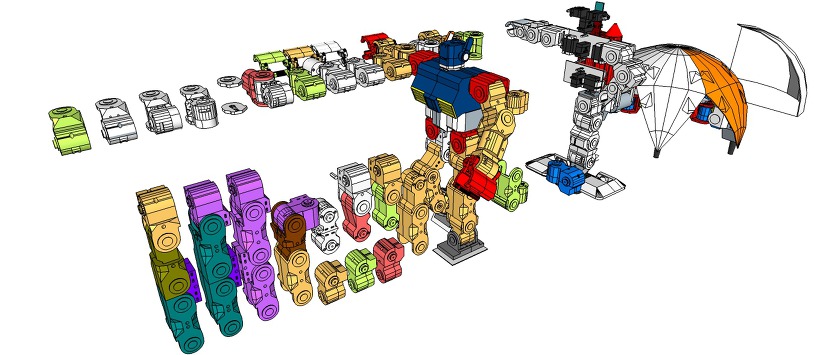

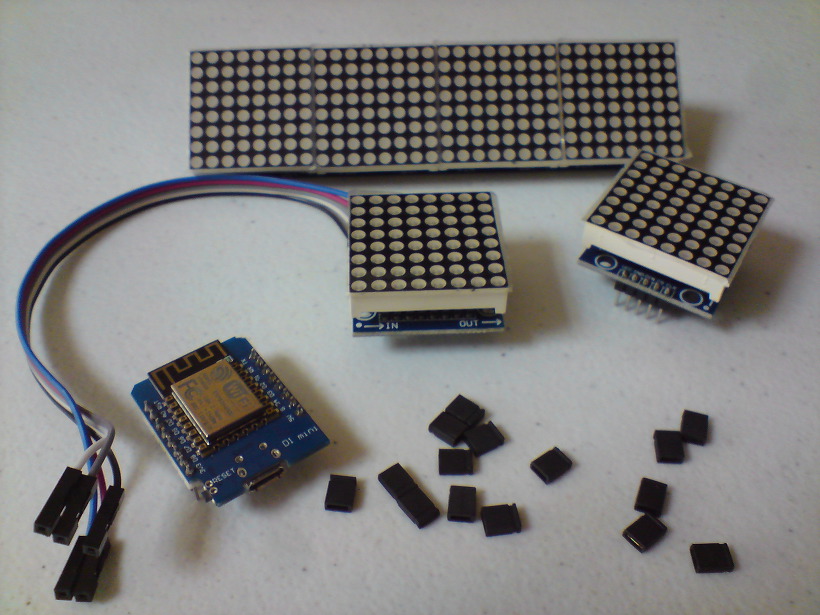

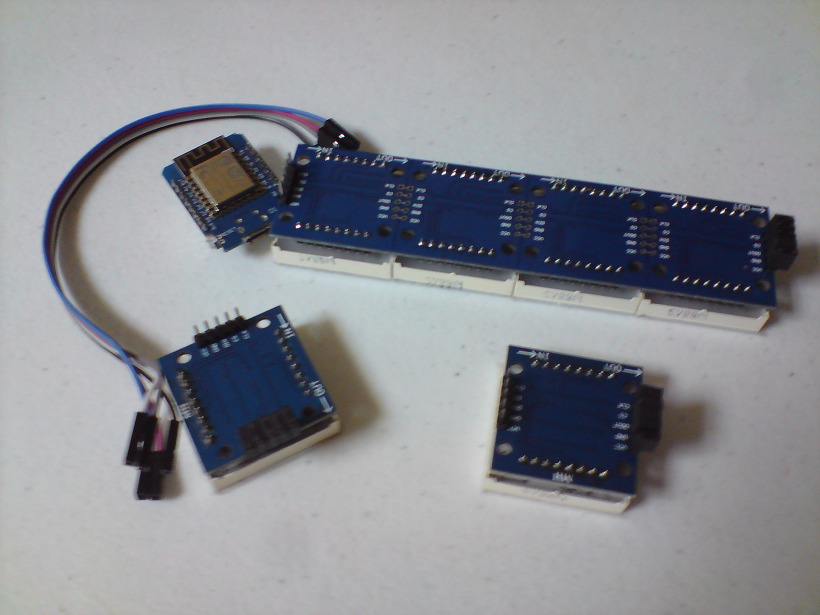

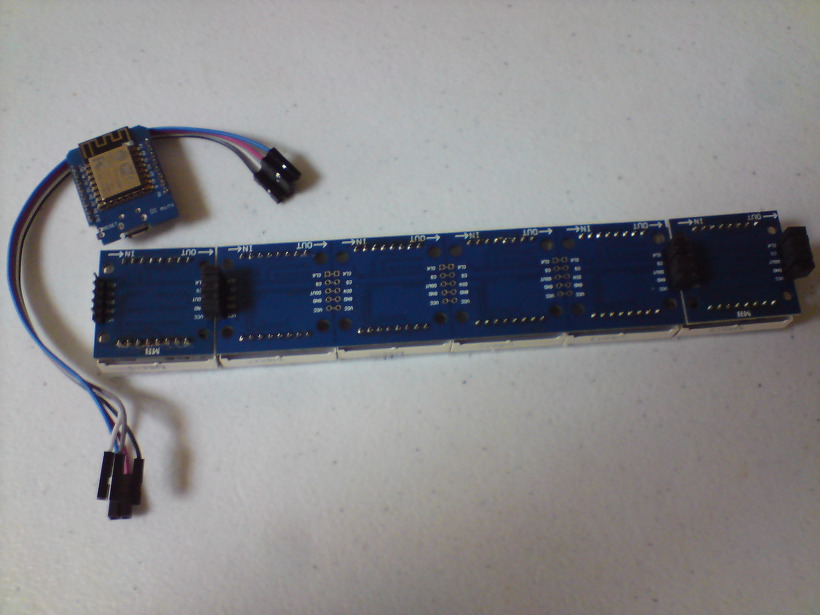

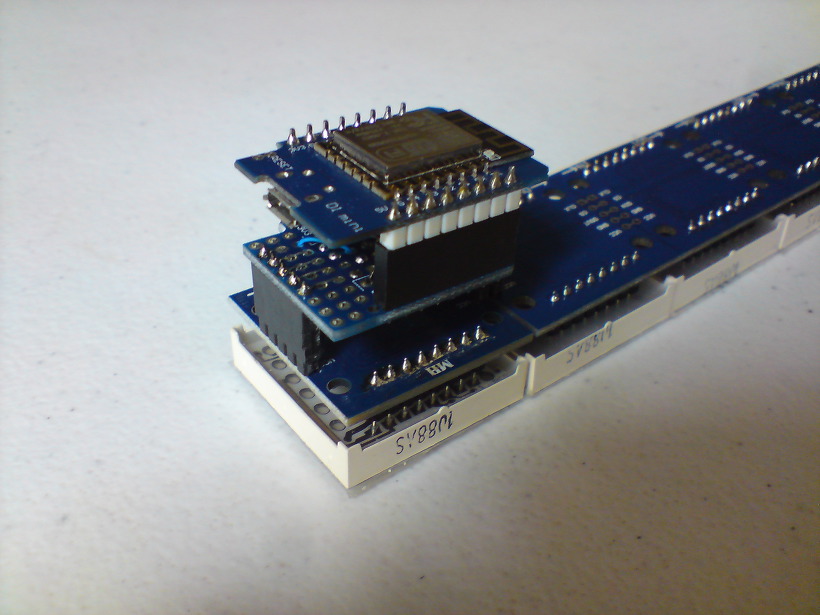

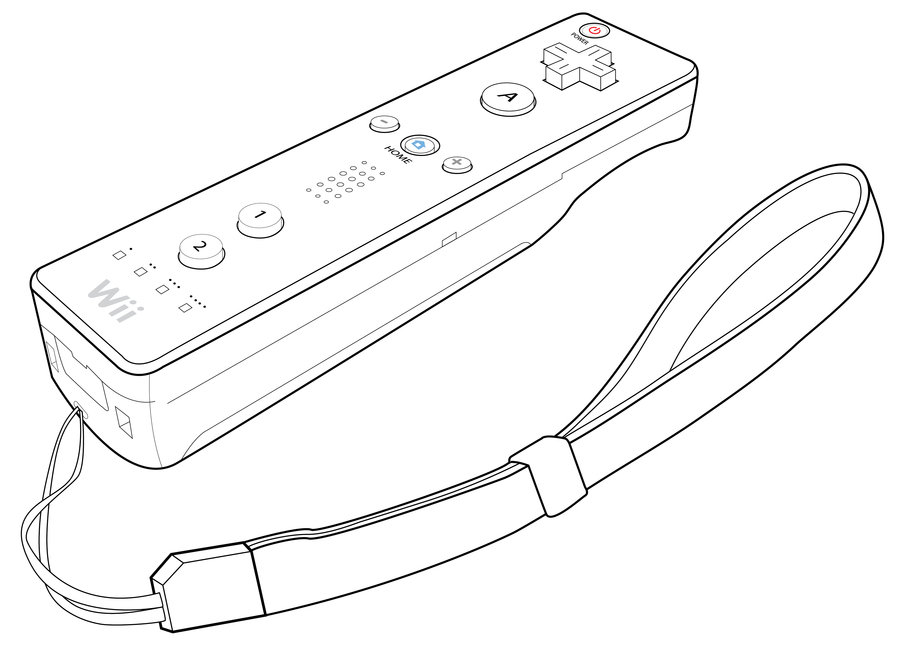

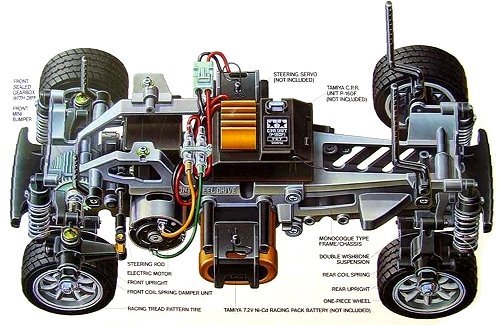

USB Host를 적용하여 Bluetooth로 직접 연결하는 방식이기 때문에 구성은 매우 간단합니다.

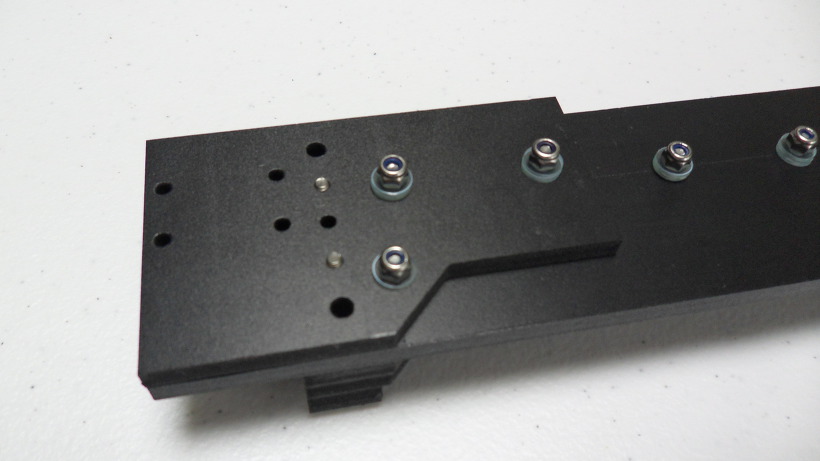

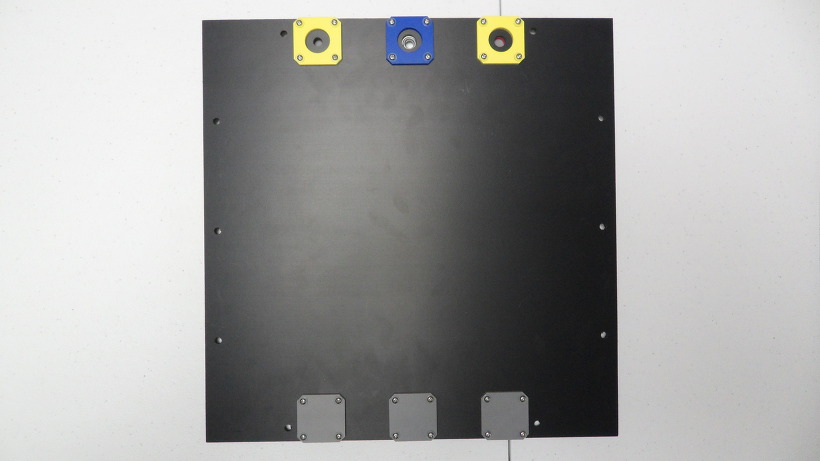

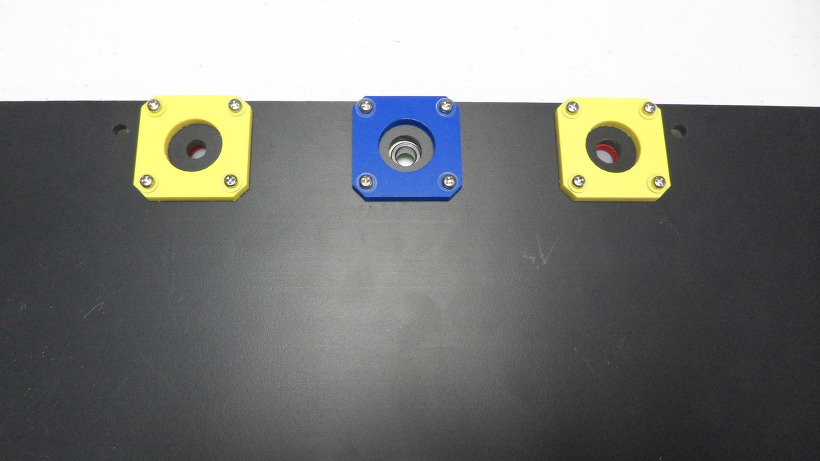

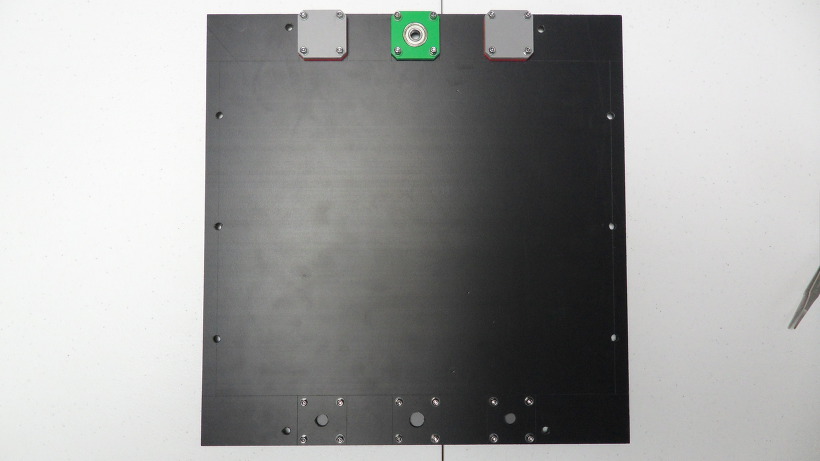

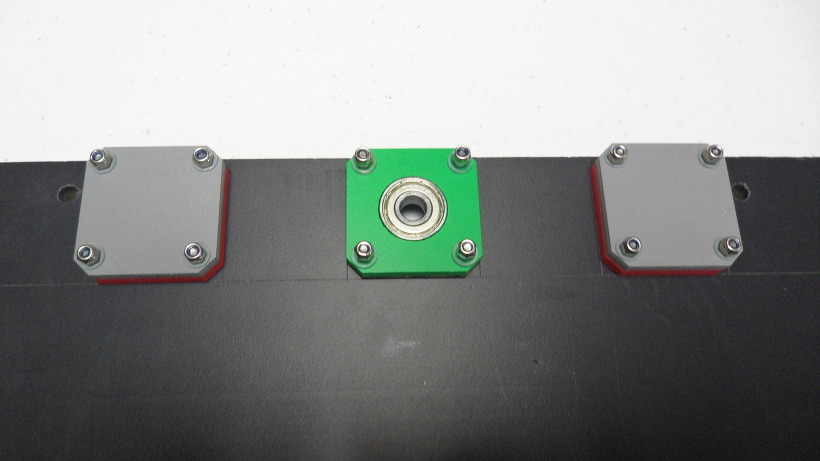

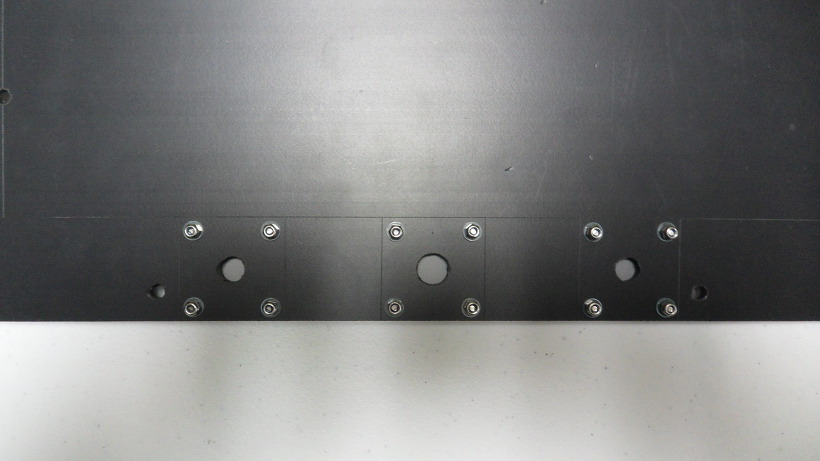

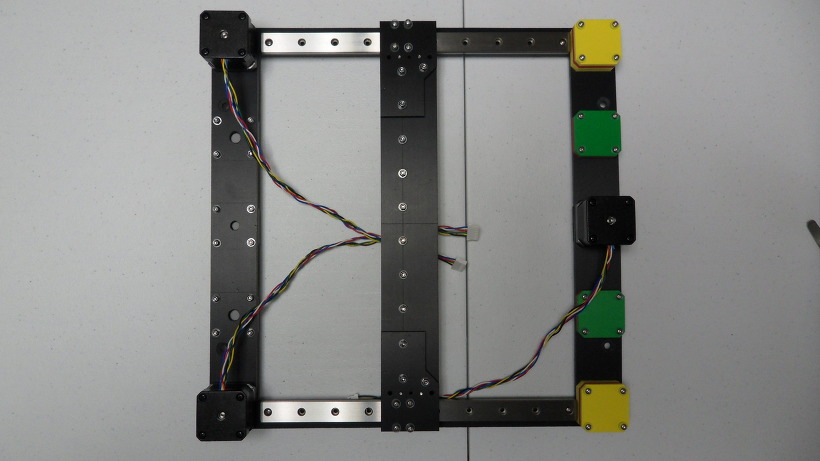

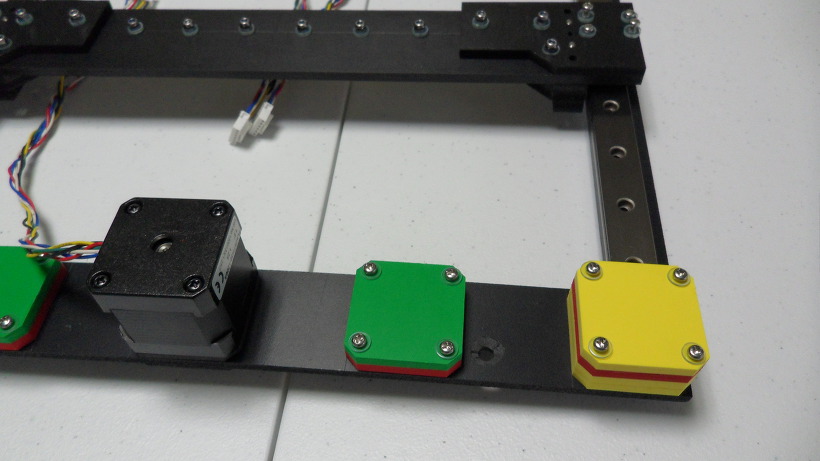

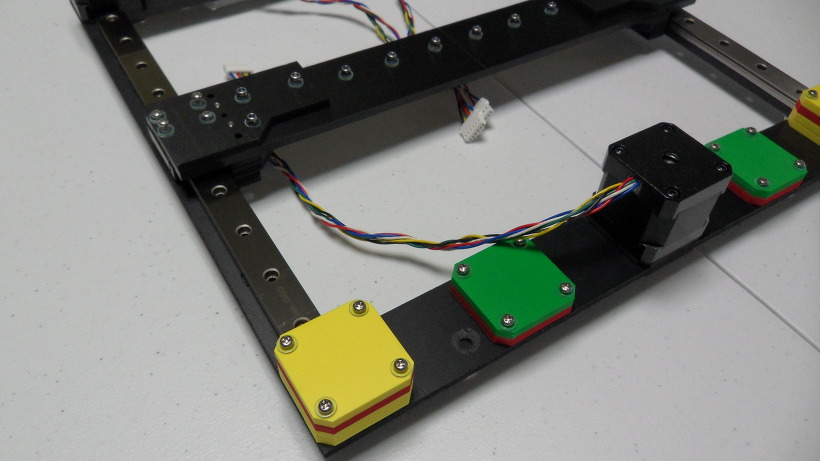

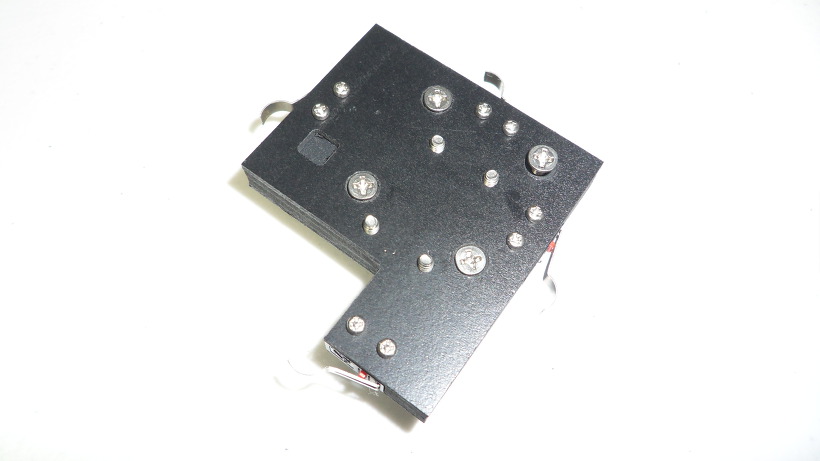

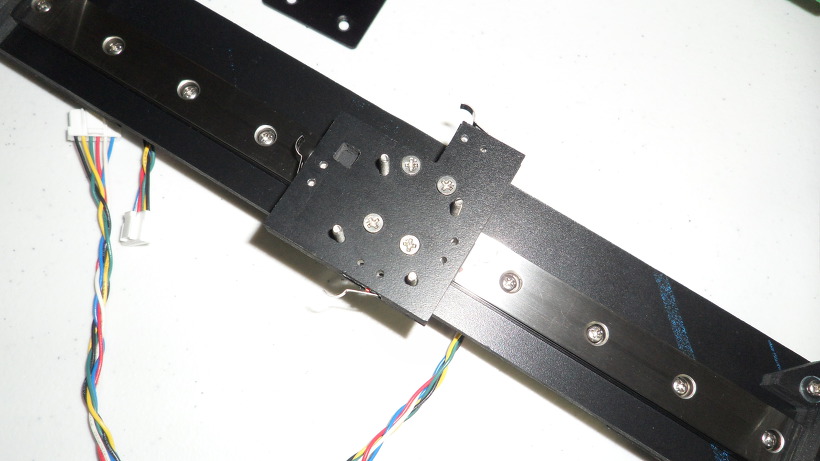

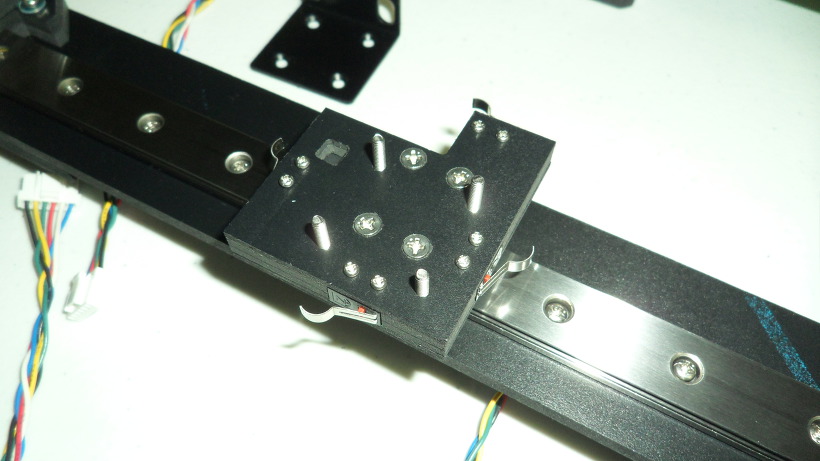

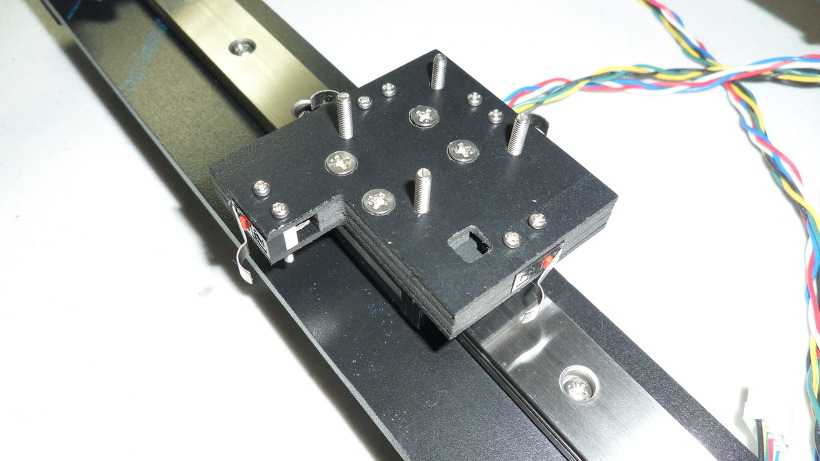

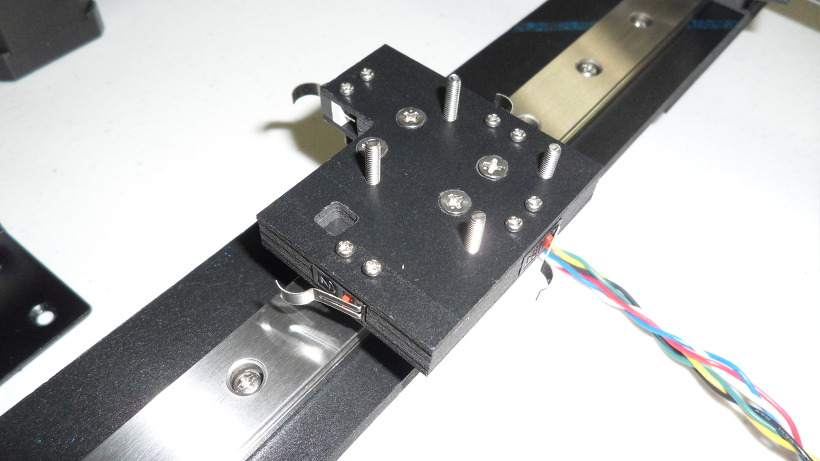

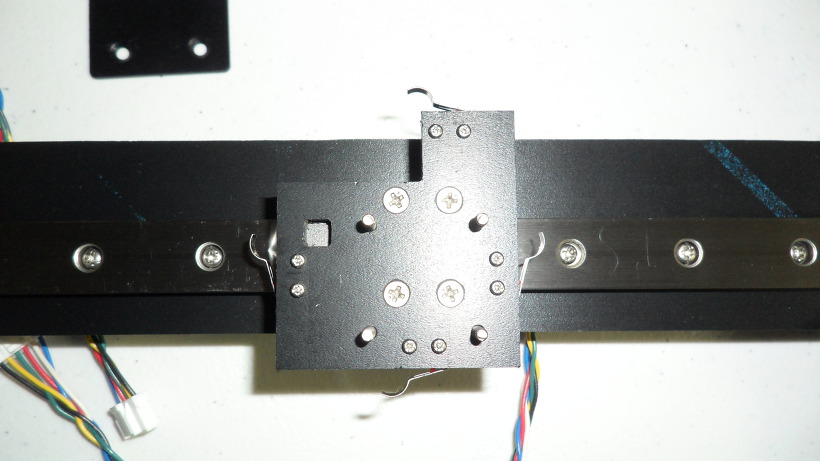

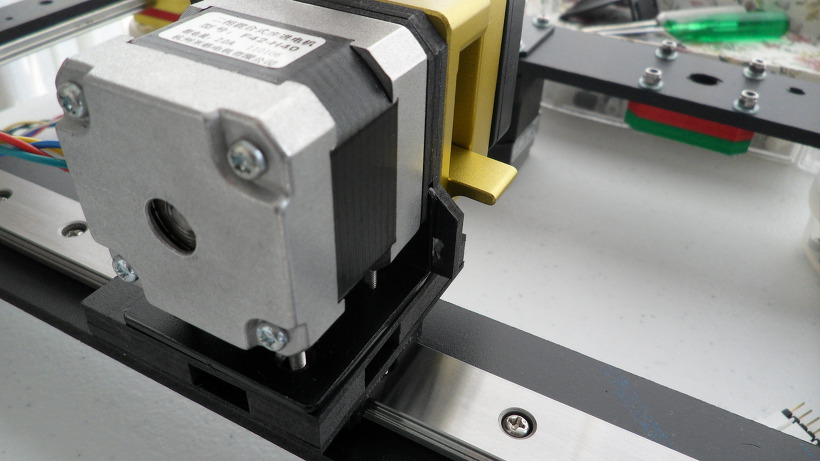

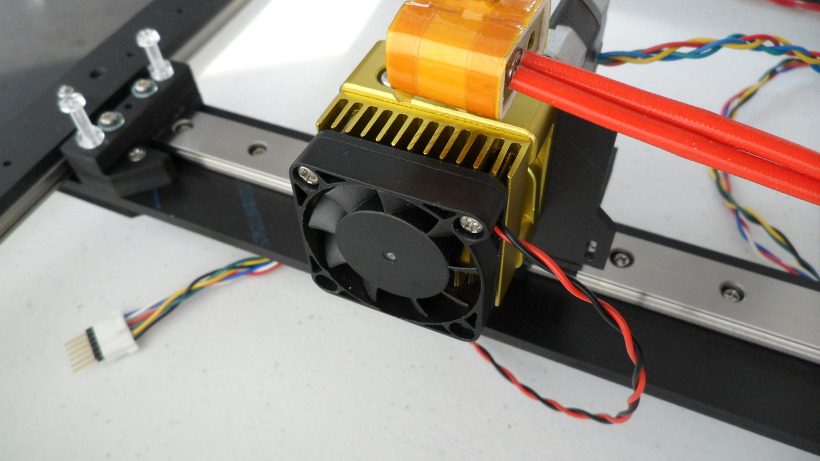

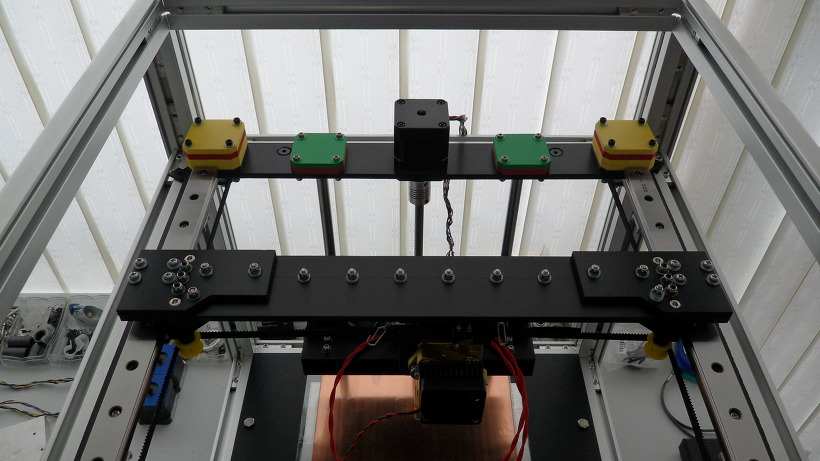

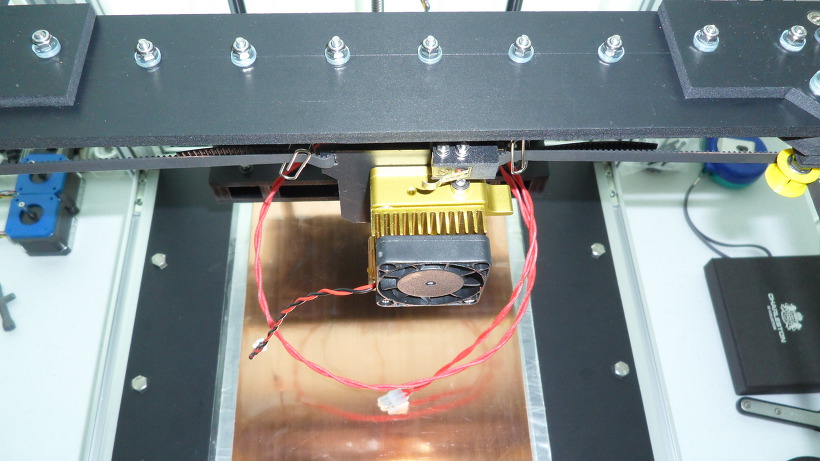

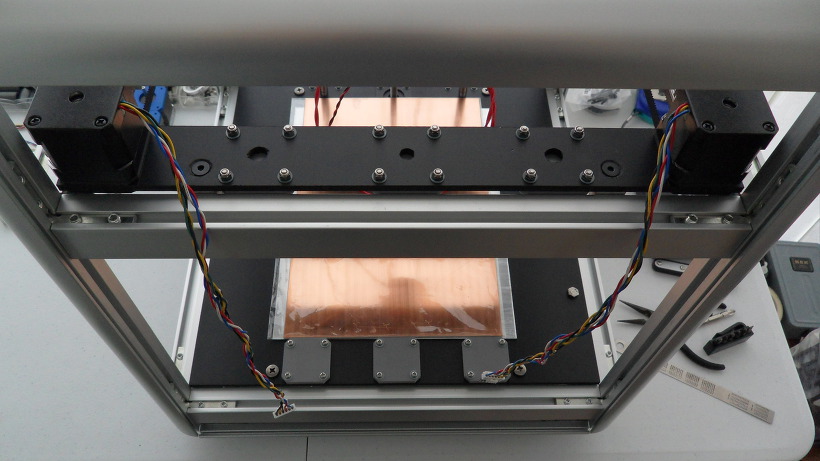

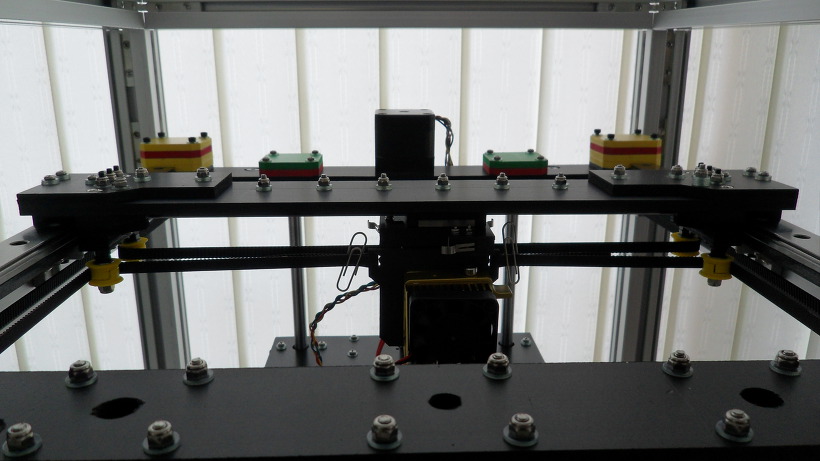

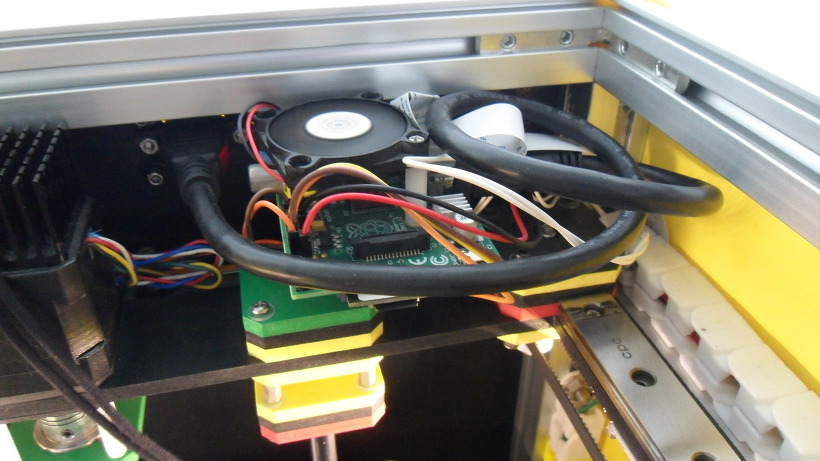

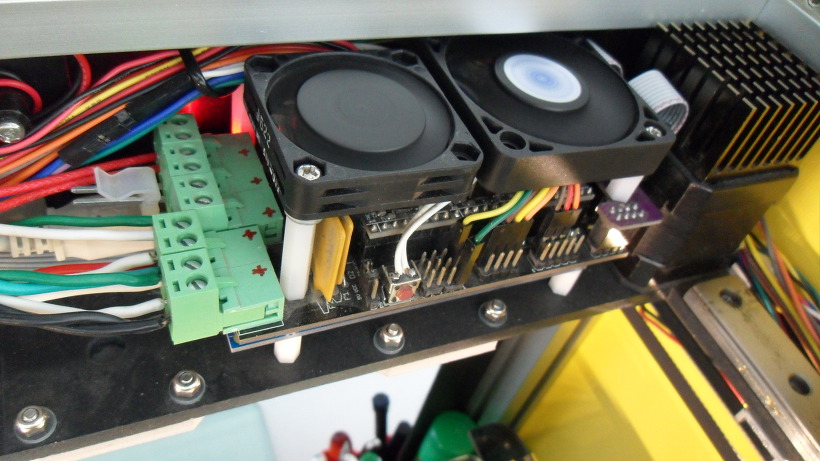

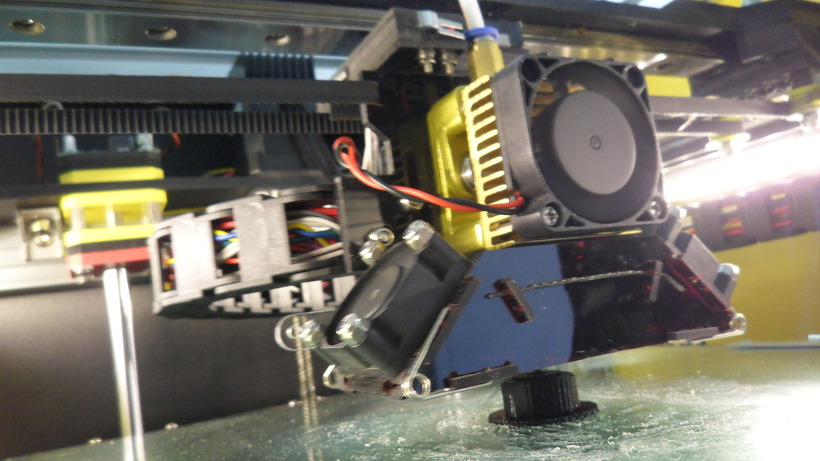

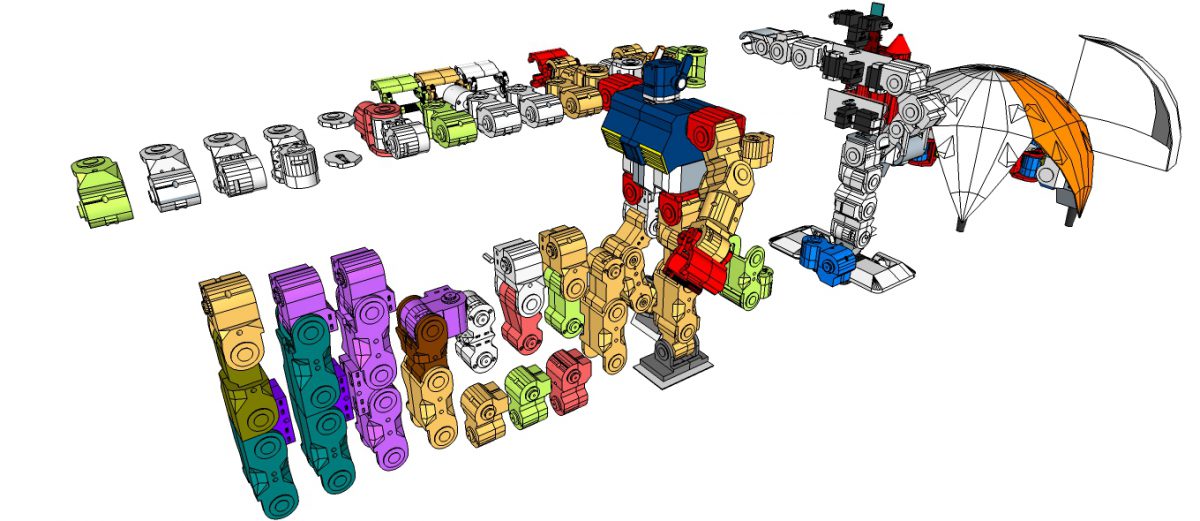

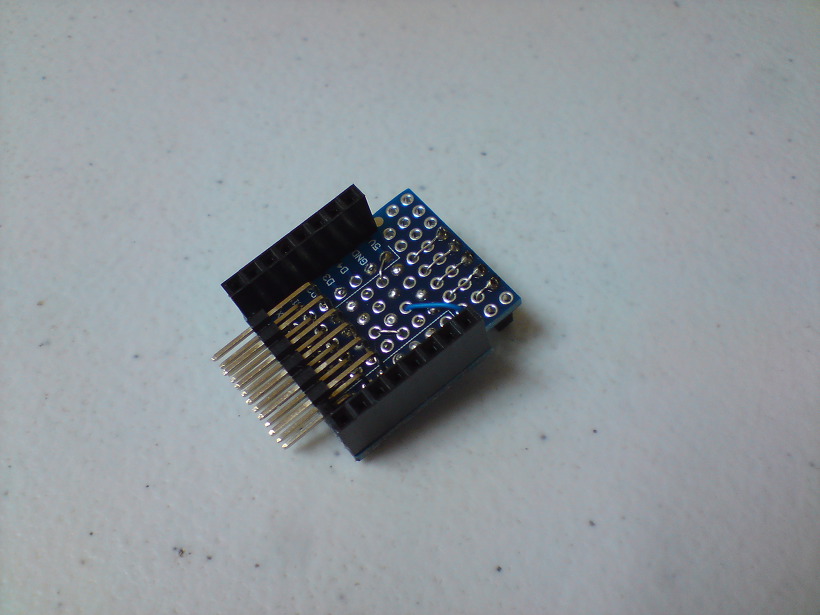

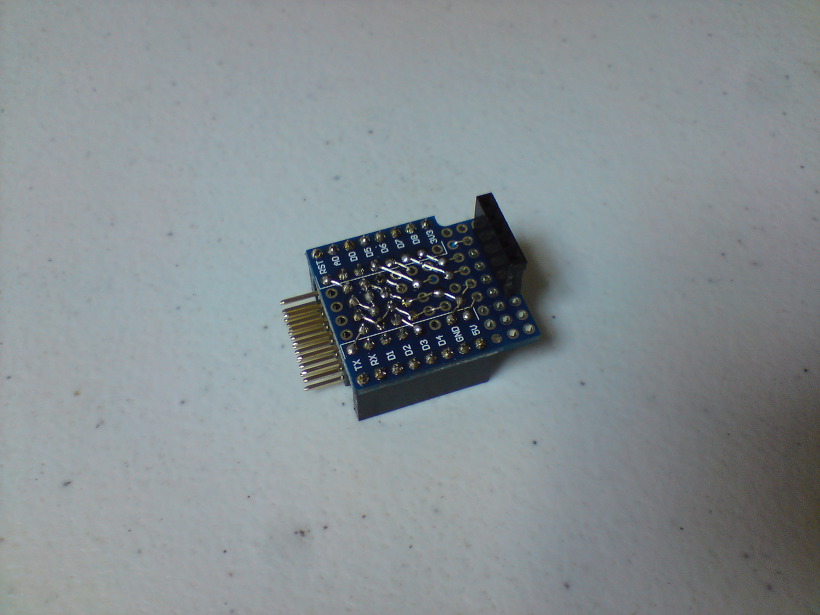

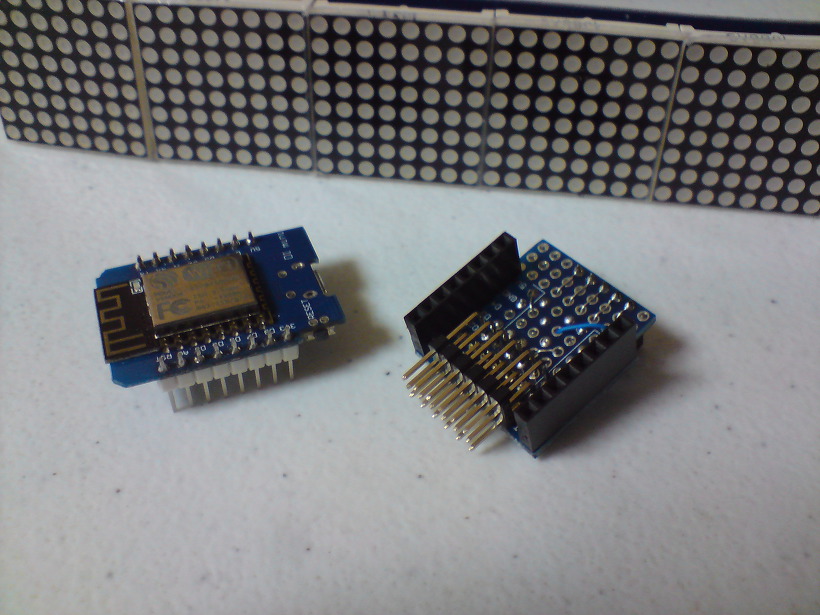

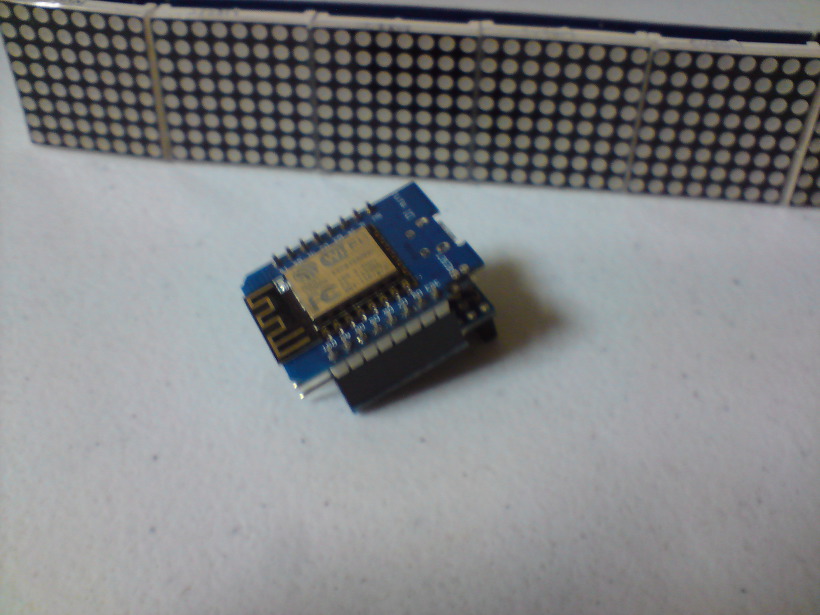

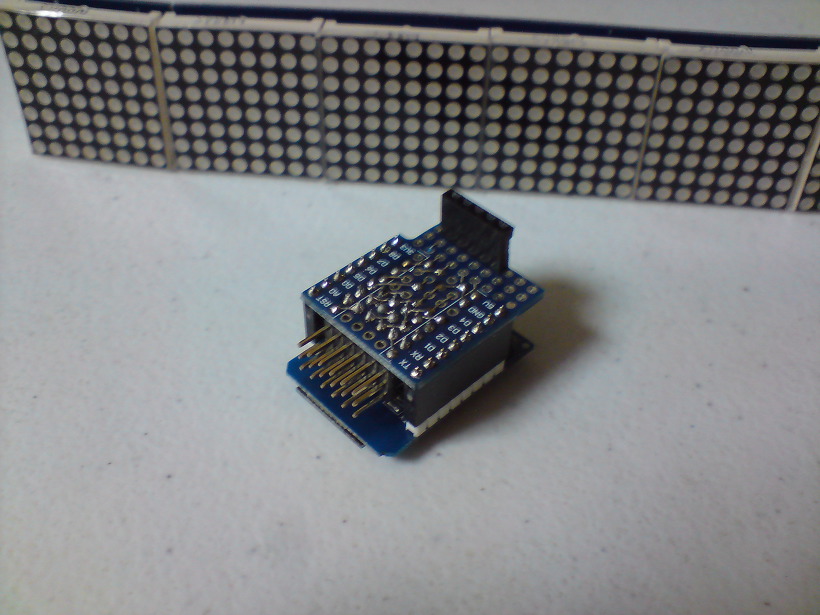

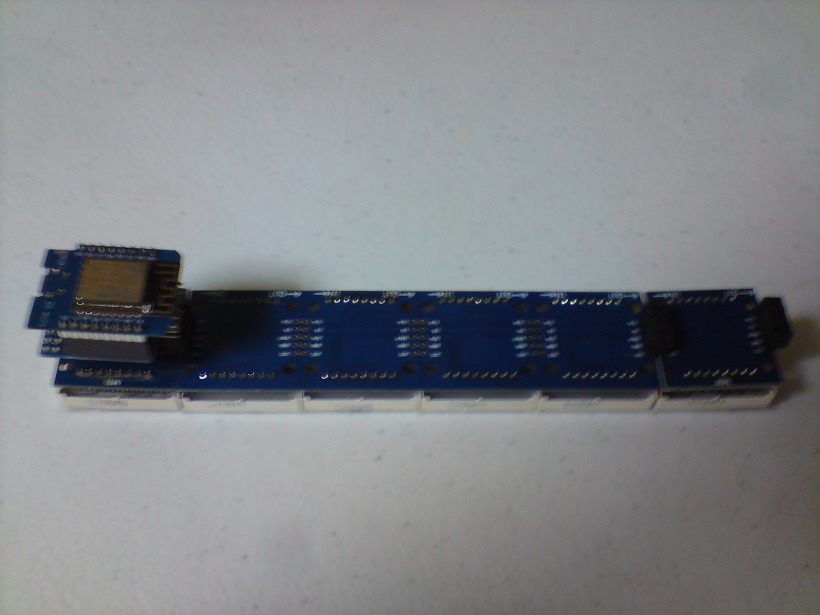

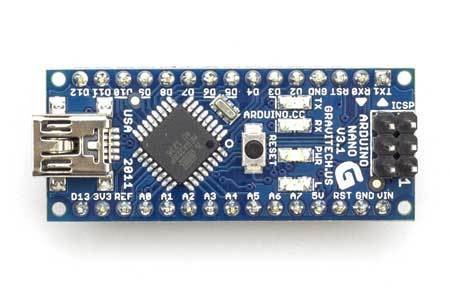

Arduino는 Nano를 사용하였고 USB Host Shield와 연결하기 위해 Mother Board를 하나 꾸며보았습니다.

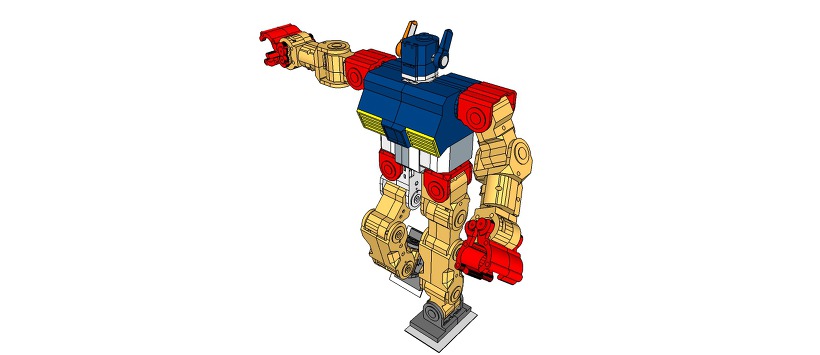

기능도 조금 추가했습니다.

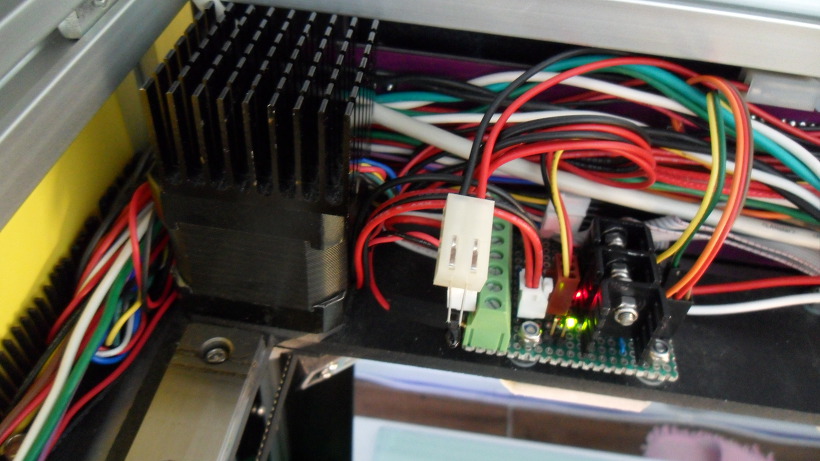

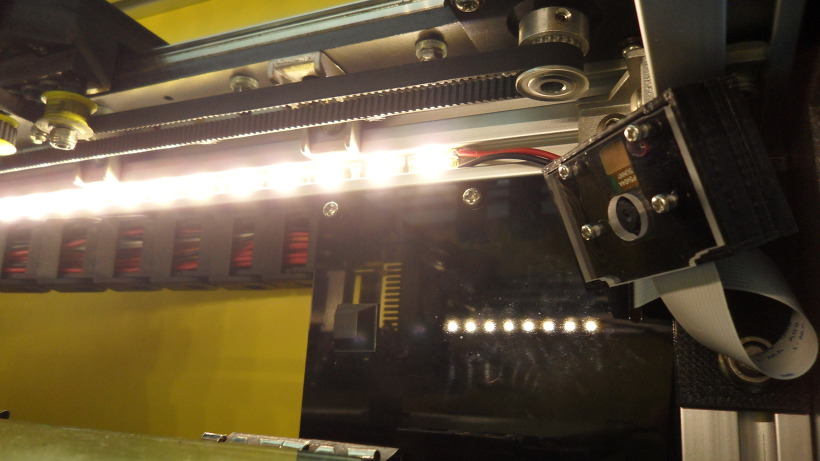

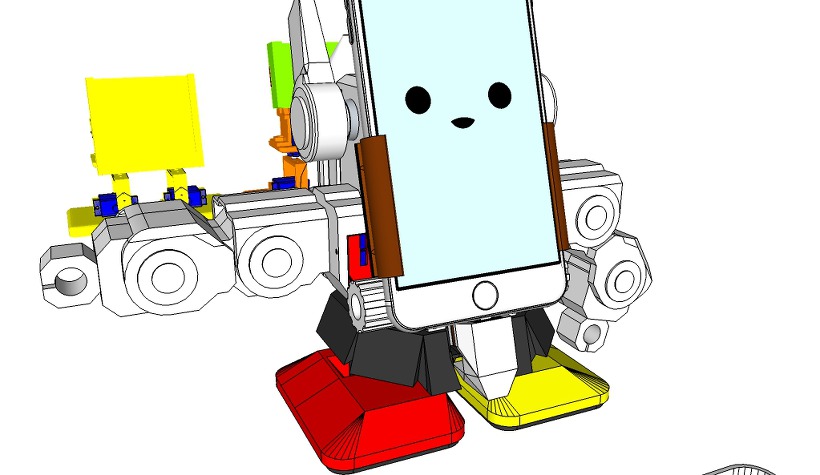

바나나를 던지거나 하지는 못하지만 “A” 버튼을 누르면 레이저가 발사되듯이 Fire LED가 켜지도록 하였고 “+” 버튼은 Head Light, “-” 버튼은 Back Light로 사용할 수 있도록 하였습니다.

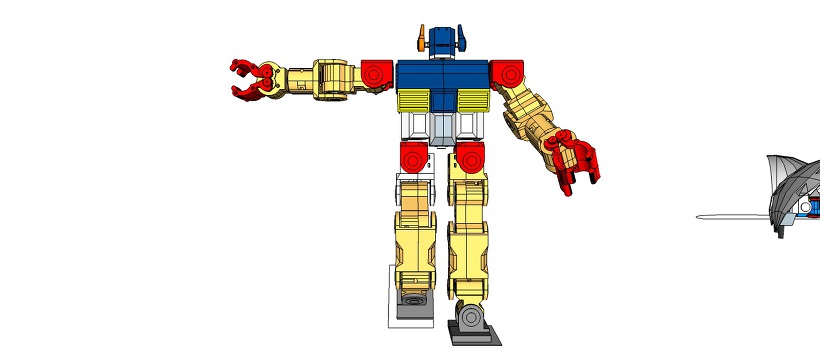

통신 거리는 Bluetooth 특성상 대략 10m 정도 밖에 안될 거라고 예상합니다만 그 이상도 충분합니다.

#include “WiiRemote.h”

#include <MemoryFree.h>

#include <Servo.h>

#define PIN_STEERING_SIGNAL 2

#define PIN_ESC_SIGNAL 4

#define PIN_HEAD_LIGHT_SIGNAL 14

#define PIN_BACK_LIGHT_SIGNAL 15

#define PIN_FIRE_SIGNAL 17

#define PIN_STEERING_SELECT 16

#define SERIAL_DEBUG 0 // 0: active mode, 1: serial debug mode

enum eAngle

{

STEERING_ANGLE_MAX = 165, // to right

STEERING_ANGLE_CENTER = 90,

STEERING_ANGLE_MIN = 15, // to left

STEERING_ANGLE_STEP = 5,

STEERING_ANGLE_MAX_INVERT = 165, // to right

STEERING_ANGLE_CENTER_INVERT = 90,

STEERING_ANGLE_MIN_INVERT = 15, // to left

THROTTLE_ANGLE_MAX = 160, // 80,

THROTTLE_ANGLE_CENTER = 90,

THROTTLE_ANGLE_MIN = 10,

};

enum eServoPulse

{

SERVO_PULSE_MAX = 2400, // to left

SERVO_PULSE_NEUTRAL = 1550, // 1500 Futaba compatible, 1.55msec

SERVO_PULSE_MIN = 600, // to right

SERVO_PULSE_MAX_INVERT = 600, // to right

SERVO_PULSE_NEUTRAL_INVERT = 1450, // 1460 Futaba compatible, 1.55msec

SERVO_PULSE_MIN_INVERT = 2400, // to left

};

enum eESCPulse

{

/*

* Futaba timing

*

* 0us 1072us 1522us 1922us

* +———*————+-*-+————-*

* | n/a | forwad |d|d| Reverse |

* +———*————+-*-+————-*

* Max Forwad Neutral Max Reverse

*

* d: dead zone, +10us and -10us

*/

ESC_PULSE_NEUTRAL = 1522,

ESC_PULSE_BRAKE = 1600,

ESC_PULSE_FWD_MAX = 800, //1200, // 1072

ESC_PULSE_FWD_MIN = 1510,

ESC_PULSE_FWD_3RD = (ESC_PULSE_FWD_MIN – 240),

ESC_PULSE_FWD_2ND = (ESC_PULSE_FWD_MIN – 160),

ESC_PULSE_FWD_1ST = (ESC_PULSE_FWD_MIN – 80),

ESC_PULSE_REV_MAX = 1700, // 1922

ESC_PULSE_REV_FIX = 1650,

ESC_PULSE_REV_MIN = 1600,

};

enum eGear

{

GEAR_1ST = 1,

GEAR_2ND = 2,

GEAR_3RD = 3,

};

WiiRemote wiiremote;

Servo SteeringServo;

Servo ESC;

void setup()

{

#if SERIAL_DEBUG

Serial.begin(115200);

Serial.print(“\r\nfreeMemory() reports: “);

Serial.print(freeMemory(), DEC);

Serial.println(“Serial connect…”);

#endif

SteeringServo.attach(PIN_STEERING_SIGNAL);

SteeringServo.writeMicroseconds(SERVO_PULSE_NEUTRAL);

ESC.attach(PIN_ESC_SIGNAL);

ESC.writeMicroseconds(ESC_PULSE_NEUTRAL);

pinMode(PIN_HEAD_LIGHT_SIGNAL, OUTPUT);

pinMode(PIN_BACK_LIGHT_SIGNAL, OUTPUT);

digitalWrite(PIN_HEAD_LIGHT_SIGNAL, LOW);

digitalWrite(PIN_BACK_LIGHT_SIGNAL, LOW);

pinMode(PIN_FIRE_SIGNAL, OUTPUT);

digitalWrite(PIN_FIRE_SIGNAL, LOW);

pinMode(PIN_STEERING_SELECT, INPUT);

digitalWrite(PIN_STEERING_SELECT, LOW);

wiiremote.init();

/*

unsigned char wiiremote_bdaddr[6] = {0x00, 0x1e, 0x35, 0xda, 0x48, 0xbc};

wiiremote.setBDAddress(wiiremote_bdaddr, 6);

wiiremote.setBDAddressMode(BD_ADDR_FIXED);

*/

#if SERIAL_DEBUG

Serial.println(“Wiimote connecting…”);

Serial.println(“Please press 1 button and 2 button simultaneously”);

#endif

}

void loop()

{

wiiremote.task(&myapp);

}

int steering_angle = STEERING_ANGLE_CENTER;

int steering_angle_invert = STEERING_ANGLE_CENTER_INVERT;

int old_steering_angle = STEERING_ANGLE_CENTER;

bool analog_throttle = false; // false = use “One” button as throttle

int throttle_angle = THROTTLE_ANGLE_CENTER;

int gear = GEAR_1ST;

int pulse_steering;

int pulse_esc;

bool fire = false; // fire

bool head_light = false; // head light

bool back_light = false; // back light

void myapp(void)

{

#if SERIAL_DEBUG

Serial.print(“\r\n”);

#endif

/* Steering */

steering_angle = getSteeringAngle();

steering_angle_invert = getSteeringAngleInvert();

if (digitalRead(PIN_STEERING_SELECT) == HIGH) {

pulse_steering = map(steering_angle,

STEERING_ANGLE_MIN, STEERING_ANGLE_MAX,

SERVO_PULSE_MAX, SERVO_PULSE_MIN);

SteeringServo.writeMicroseconds(pulse_steering);

} else {

pulse_steering = map(steering_angle_invert,

STEERING_ANGLE_MIN_INVERT, STEERING_ANGLE_MAX_INVERT,

SERVO_PULSE_MAX_INVERT, SERVO_PULSE_MIN_INVERT);

SteeringServo.writeMicroseconds(pulse_steering);

}

if (wiiremote.buttonPressed(WIIREMOTE_UP)) {

steering_angle = STEERING_ANGLE_MIN;

steering_angle_invert = STEERING_ANGLE_MIN_INVERT;

if (digitalRead(PIN_STEERING_SELECT) == HIGH) {

pulse_steering = map(steering_angle, STEERING_ANGLE_MIN, STEERING_ANGLE_MAX, SERVO_PULSE_MAX, SERVO_PULSE_MIN);

SteeringServo.writeMicroseconds(pulse_steering);

} else {

pulse_steering = map(steering_angle_invert, STEERING_ANGLE_MIN_INVERT, STEERING_ANGLE_MAX_INVERT, SERVO_PULSE_MAX_INVERT, SERVO_PULSE_MIN_INVERT);

SteeringServo.writeMicroseconds(pulse_steering);

}

} else if (wiiremote.buttonPressed(WIIREMOTE_DOWN)) {

steering_angle = STEERING_ANGLE_MAX;

steering_angle_invert = STEERING_ANGLE_MAX_INVERT;

if (digitalRead(PIN_STEERING_SELECT) == HIGH) {

pulse_steering = map(steering_angle, STEERING_ANGLE_MIN, STEERING_ANGLE_MAX, SERVO_PULSE_MAX, SERVO_PULSE_MIN);

SteeringServo.writeMicroseconds(pulse_steering);

} else {

pulse_steering = map(steering_angle_invert, STEERING_ANGLE_MIN_INVERT, STEERING_ANGLE_MAX_INVERT, SERVO_PULSE_MAX_INVERT, SERVO_PULSE_MIN_INVERT);

SteeringServo.writeMicroseconds(pulse_steering);

}

}

#if SERIAL_DEBUG

Serial.print(“\tServo=”);

Serial.print(pulse_steering);

#endif

/* Brake and Throttle */

if (wiiremote.buttonPressed(WIIREMOTE_ONE)) {

if (pulse_esc < ESC_PULSE_NEUTRAL) {

// moving forward before press “One”

brake();

pulse_esc = ESC_PULSE_NEUTRAL;

} else {

// while stopping or moving backward, keep moving backward

pulse_esc = ESC_PULSE_REV_FIX;

}

} else {

if (analog_throttle) {

throttle_angle = getThrottleAngle();

pulse_esc = map(throttle_angle,

THROTTLE_ANGLE_MIN, THROTTLE_ANGLE_MAX,

ESC_PULSE_FWD_MIN, ESC_PULSE_FWD_MAX);

} else if (wiiremote.buttonPressed(WIIREMOTE_TWO)) {

switch (gear) {

case GEAR_1ST:

pulse_esc = ESC_PULSE_FWD_1ST;

break;

case GEAR_2ND:

pulse_esc = ESC_PULSE_FWD_2ND;

break;

case GEAR_3RD:

pulse_esc = ESC_PULSE_FWD_3RD;

break;

default:

pulse_esc = ESC_PULSE_NEUTRAL;

break;

}

} else {

pulse_esc = ESC_PULSE_NEUTRAL;

}

}

ESC.writeMicroseconds(pulse_esc);

//delay(15);

#if SERIAL_DEBUG

Serial.print(“\tESC=”);

Serial.print(pulse_esc);

#endif

/* Throttle mode */

if (wiiremote.buttonClicked(WIIREMOTE_HOME)) {

analog_throttle = !analog_throttle;

if (analog_throttle) {

wiiremote.setLED(WIIREMOTE_LED4); // analog mode

} else {

wiiremote.setLED(WIIREMOTE_LED1); // fixed mode, 1st gear

gear = GEAR_1ST;

}

}

/* Shift up or down */

if (!analog_throttle) {

if (wiiremote.buttonClicked(WIIREMOTE_RIGHT)) {

shiftUp();

} else if (wiiremote.buttonClicked(WIIREMOTE_LEFT)) {

shiftDown();

}

}

/* Fire */

if (wiiremote.buttonPressed(WIIREMOTE_A)) {

digitalWrite(PIN_FIRE_SIGNAL, HIGH);

} else {

digitalWrite(PIN_FIRE_SIGNAL, LOW);

}

/* Head light LED */

if (wiiremote.buttonClicked(WIIREMOTE_PLUS)) {

head_light = !head_light;

if (head_light) {

digitalWrite(PIN_HEAD_LIGHT_SIGNAL, HIGH);

} else {

digitalWrite(PIN_HEAD_LIGHT_SIGNAL, LOW);

}

}

/* Back light LED */

if (wiiremote.buttonClicked(WIIREMOTE_MINUS)) {

back_light = !back_light;

if (back_light) {

digitalWrite(PIN_BACK_LIGHT_SIGNAL, HIGH);

} else {

digitalWrite(PIN_BACK_LIGHT_SIGNAL, LOW);

}

}

} // myapp

int getSteeringAngle(void)

{

double rad;

int deg;

rad = acos((double) wiiremote.Report.Accel.Y);

deg = (int) (rad * 180.0 / PI);

/* clipping */

if (deg > STEERING_ANGLE_MAX) { deg = STEERING_ANGLE_MAX; }

if (deg < STEERING_ANGLE_MIN) { deg = STEERING_ANGLE_MIN; }

return deg;

}

int getSteeringAngleInvert(void)

{

double rad;

int deg;

rad = acos((double) wiiremote.Report.Accel.Y);

deg = (int) (rad * 180.0 / PI);

/* clipping */

if (deg > STEERING_ANGLE_MAX_INVERT) { deg = STEERING_ANGLE_MAX_INVERT; }

if (deg < STEERING_ANGLE_MIN_INVERT) { deg = STEERING_ANGLE_MIN_INVERT; }

return deg;

}

int getThrottleAngle(void)

{

double rad;

double compensate_z;

int deg;

rad = asin((double) wiiremote.Report.Accel.Y);

compensate_z = (double) wiiremote.Report.Accel.Z / cos(rad);

rad = asin(compensate_z);

deg = (int) (rad * 180.0 / PI);

/* clipping */

if (deg > THROTTLE_ANGLE_MAX) { deg = THROTTLE_ANGLE_MAX; }

if (deg < THROTTLE_ANGLE_MIN) { deg = THROTTLE_ANGLE_MIN; }

return deg;

}

inline void brake(void)

{

ESC.writeMicroseconds(ESC_PULSE_BRAKE);

delay(15);

ESC.writeMicroseconds(ESC_PULSE_NEUTRAL);

delay(15);

}

inline void shiftUp(void)

{

if (gear < GEAR_3RD) {

gear++;

wiiremote.setLED( (WIIREMOTE_LED1 << (gear – GEAR_1ST)) );

}

}

inline void shiftDown(void)

{

if (gear > GEAR_1ST) {

gear–;

wiiremote.setLED( (WIIREMOTE_LED1 << (gear – GEAR_1ST)) );

}

}